(3) Center axle and tube assembly (((and slide both

axle collars (6) against frames (4). Secure collars into position

by tightening two screws (5 (in each collar.

(4) Position ring (3, fig. 6-9) on axle and screw on

cap (8). Place ring (3) and elbow assembly (1) on other end of

axle; secure elbow assembly with screw (2).

(5) Position two secured-end arm brackets (1 1)

and secure each with six screws (14).

(6)

Reassemble the cross brace assembly (5, fig. 6-

8) as follows:

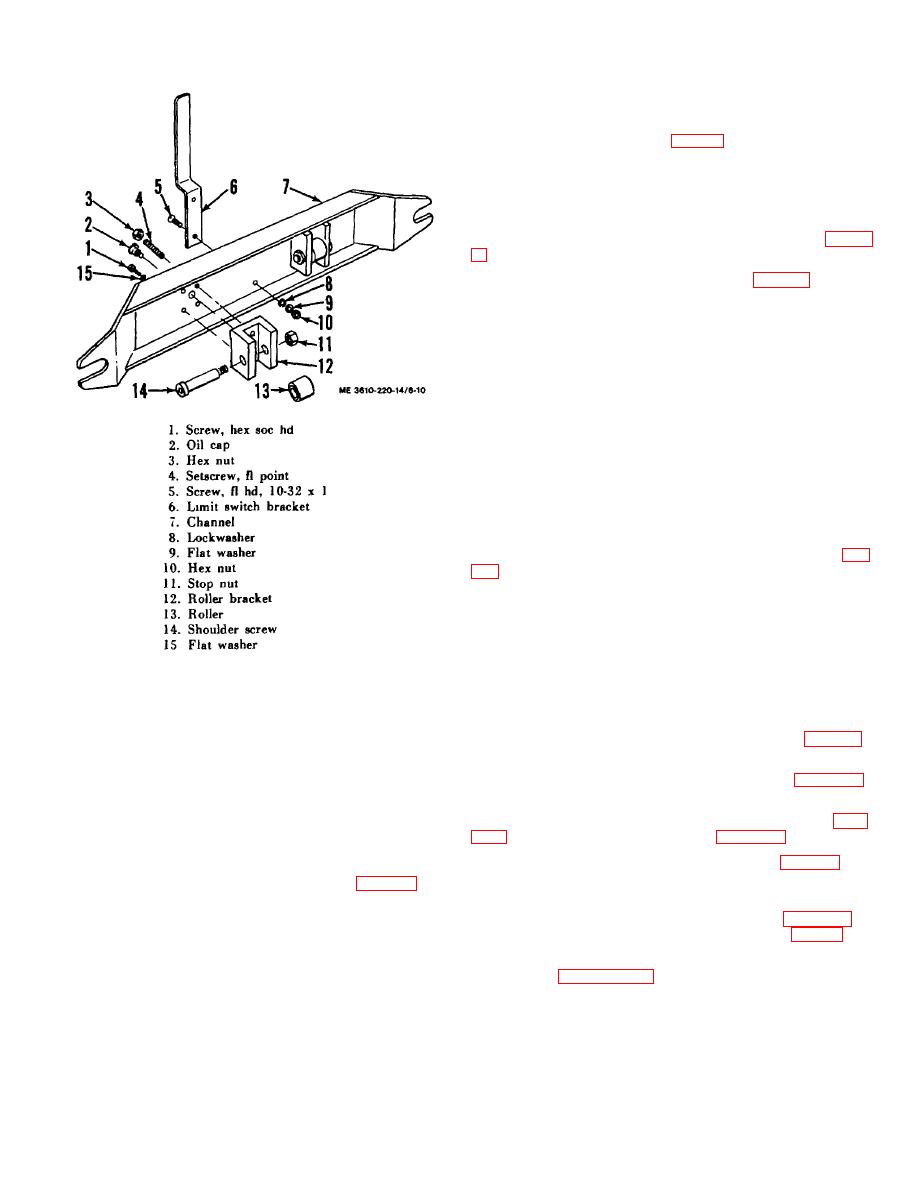

(a) Position roller (13, fig. 6-10) in roller

bracket (12 (and tap in shoulder screw (14). Secure screw with

a new stop nut (11) to prevent the possibility of the old stop nut

from working free from the shoulder screw and causing damage

to the base plate and camera bed.

(b) Position roller assembly in cross

brace channel (hi and secure with two set screws (4l, two nuts

(3l, two screws (1) and two flatwashers (15-. Assemble and

install remaining roller in the same manner.

(c) Install oiler (2).

(d) Position limit switch bracket (6) and

secure with screws (5l, lockwashers (8l, flat-washers (9) and

nuts (10).

b. Installation.

(1) Position copyboard carriage assembly on

camera rail and secure to four side bearing block gibe (13, fig.

gibe draw carriage snugly to rail to provide a sliding fit without

shake or play. Use shims if necessary to take up wear and

play. If wear is pronounced, also check rail for wear as setting

the gibe properly in the center of movement of the copyboard

carriage may result in binding at the extremes. Check for wear

by placing a precision straight edge on the rail. Low spots will

be visible below the straight edge, or can be determined with

Figure 6-10. Cross brace assembly, exploded view.

shims. If rail is worn, it should be scraped into a uniform and

true sliding with the carriage.

6-19. Copyboard Carriage Cleaning and Inspection

Clean all parts thoroughly with a cleaning solvent and a clean

(2) Install the cross brace assembly (5, fig. 6-8)

cloth, being certain to reach threaded areas. Examine threaded

with two hinge pin nuts (6) and washers (7).

areas for stripped and damaged condition. Inspect all parts for

(3)

Install the copyboard locking device (para 4-53.

cracked or broken condition. Check rollers, gibe, and shims for

d.1

wear and burred working surface, and the axle and tube

assembly for warping. Replace defective parts.

(4) Install the transparancy holder assembly (para

6-20. Copyboard Carriage Reassembly

(5) Replace new oil felt wiper (11, fig. 6-8) on

a. Reassembly.

copyboard carriage base plate (3) and install with wiper guards

(1) Position copyboard frame (4, fig. 6-9) on

(9) and screws (101. Lubricate all four wipers.

carriage base plate (10) and attach with four hex socket head

screws (18). Drive in two dowel pins (17).

(6) Install the arc lamp arm assembly (para 4-30.1)

and position arc lamps on free-end arm bracket (14, fig. 4-6).

(2) Slide an axle collar (6) on each end of axle but

do not tighten screws (5). Insert one end of axle into installed

c. Calibratin. Calibrate the copyboard to the lens

frame and, while supporting weight of axle and tube assembly,

as detailed in paragraph 5-6. b.

slide remaining frame into position and secure frame to carriage

base plate (10) with four hex socket head screws (181. Drive in

two dowel pins (171.

6-10