Check the assembly for overall warping. Examine the operating

knob for satisfactory operation. If any part of the copyboard

assembly is defective, report the condition to the proper

authority.

d. Installation.

(1) Install the copyboard (1, fig. 4-27) on the axle

and tube assembly (4), being sure that it sits flush.

(2) Turn the copyboard counterclockwise so that

the locking devices (2) are inserted in the slots of the copyboard

flange. Tighten the hand knobs.

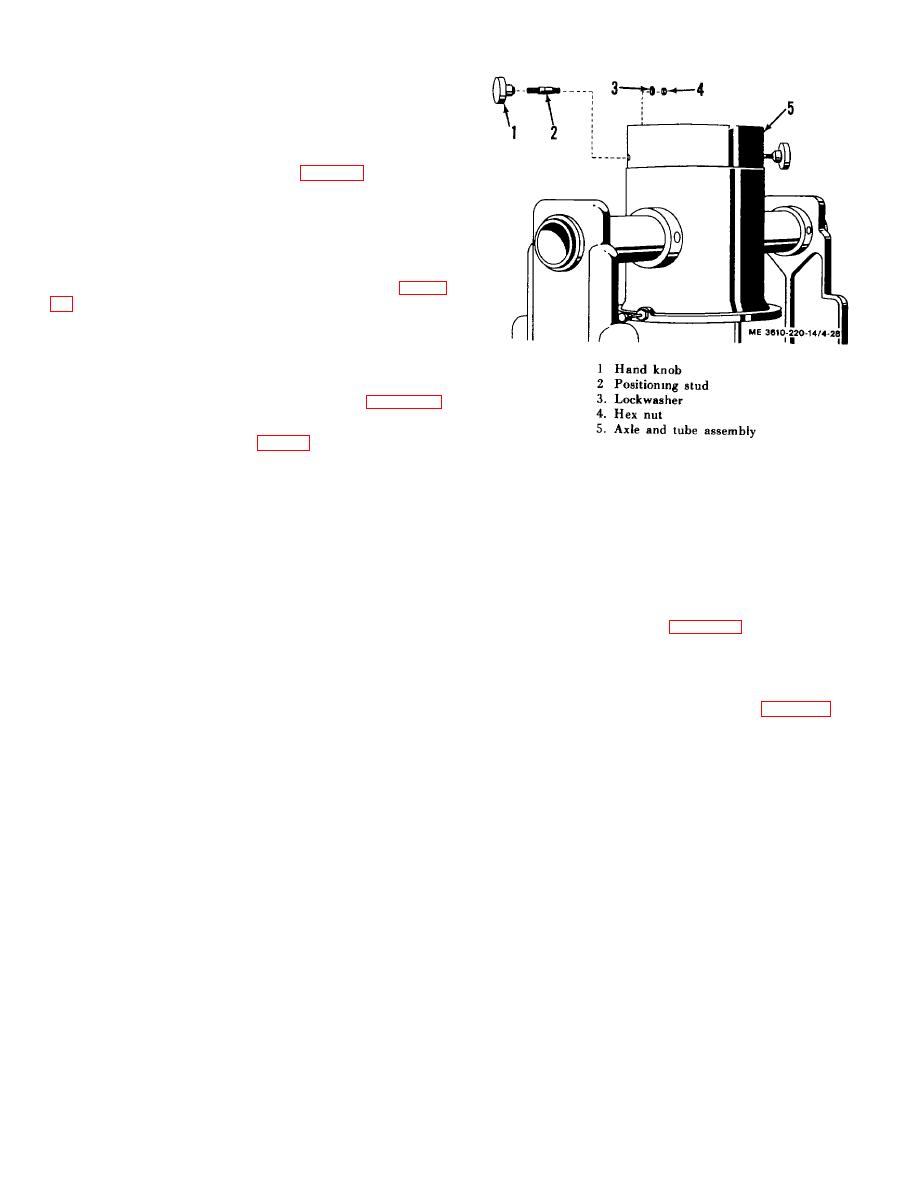

4-53. Copyboard locking Device

of a positioning stud with a hand knob threaded on the exterior

end and a lockwasher and nut on the inner end holding it to the

tube.

b. Removal.

(1)

Remove the copyboard assembly (para 4-52.

b.).

(2)

Unscrew knob (1, fig.4-28) from positioning stud

(2).

Figure 4-28. Copyboard locking device, exploded

(3) From the inside of axle and tube assembly (5),

view.

remove nut (4) and lockwasher (3) from stud (2). Tap out the

stud.

c. Cleaning and Inspection. Clean the parts with cleaning

solvent and dry with a clean, soft cloth. Inspect the hand knob

and positioning stud for worn threads, bends, and breaks.

Replace defective parts if necessary.

d. Installation.

(1) Place stud (2, fig. 4-28) in axle and tube

assembly (5). From the inside of axle and tube assembly (5),

install nut (4) and lockwasher (3) on stud (2).

(2)

Screw knob (1) on stud (2).

(3)

Install the copyboard assembly (para 4-52. d.).

4-30