4-44. Drive Motors

c. Cleaning and Inspection. Clean the outside casing of

the drive motor with a cloth dampened with cleaning solvent.

Inspect the motor for damaged casing and bent shaft. Apply a

and copyboard drive motor (20) have an electrical rating of 208

208 volt external source to motor wires and check operation.

volt, 3 phase, 60 cycle frequency.

The motors contain

Replace defective drive motor if necessary.

permanently sealed bearings requiring no lubrication.

d. Installation.

b. Removal.

(1) Position drive motor (14 or 20) on motor

(1)

Disconnect wire cable from terminal outlet box.

support bracket (17), aligning motor gear with driven gear on

(2)

Remove four nuts (19) to release drive motor

drivescrew.

(14 and 20).

(2) Retain drive motor on motor support bracket

(3) Lift the motor from the motor support bracket

with four nuts (19).

(17) being careful not to damage motor gear.

(3)

Attach wires to terminal outlet box.

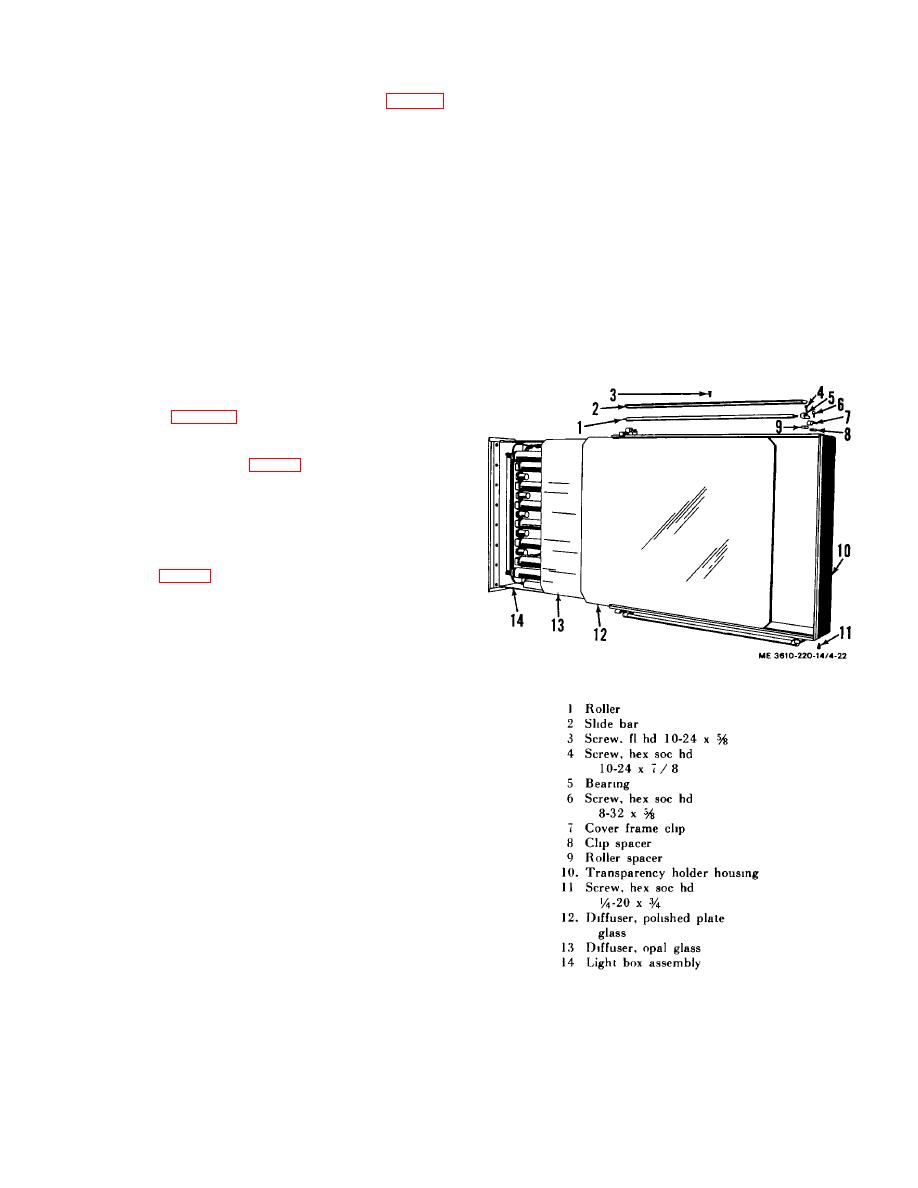

Section XIII. MAINTENANCE OF TRANSPARENCY HOLDER

ASSEMBLY AND DIVERTER VALVE PLATE ASSEMBLY

4-45. Description

The transparency holder assembly consists of a housing light

box assembly (14, fig. 4-22), opal glass diffuser (13), and a

polished plate glass diffuser (12). The transparency holder

housing, the main structure of the assembly, is rigidly bolted to

the axle and tube assembly (3, fig. 1-6) to assure that its front

surface is of equal distance from the axis of rotation and

parallel to that of the copyboard. A diverter valve plate

assembly, secured to the transparency holder housing, controls

the suction flow through the assembly. The light box assembly,

mounted in the housing, contains fluorescent tubes to supply

the necessary illumination for copying transparencies. Mounted

on slide bars (14, fig. 1-6) on the top and bottom of the housing

are aerial film brackets (1) used to roll aerial film over the

diffuser.

Figure 4-22. Transparency holder assembly,

exploded view.

4-25