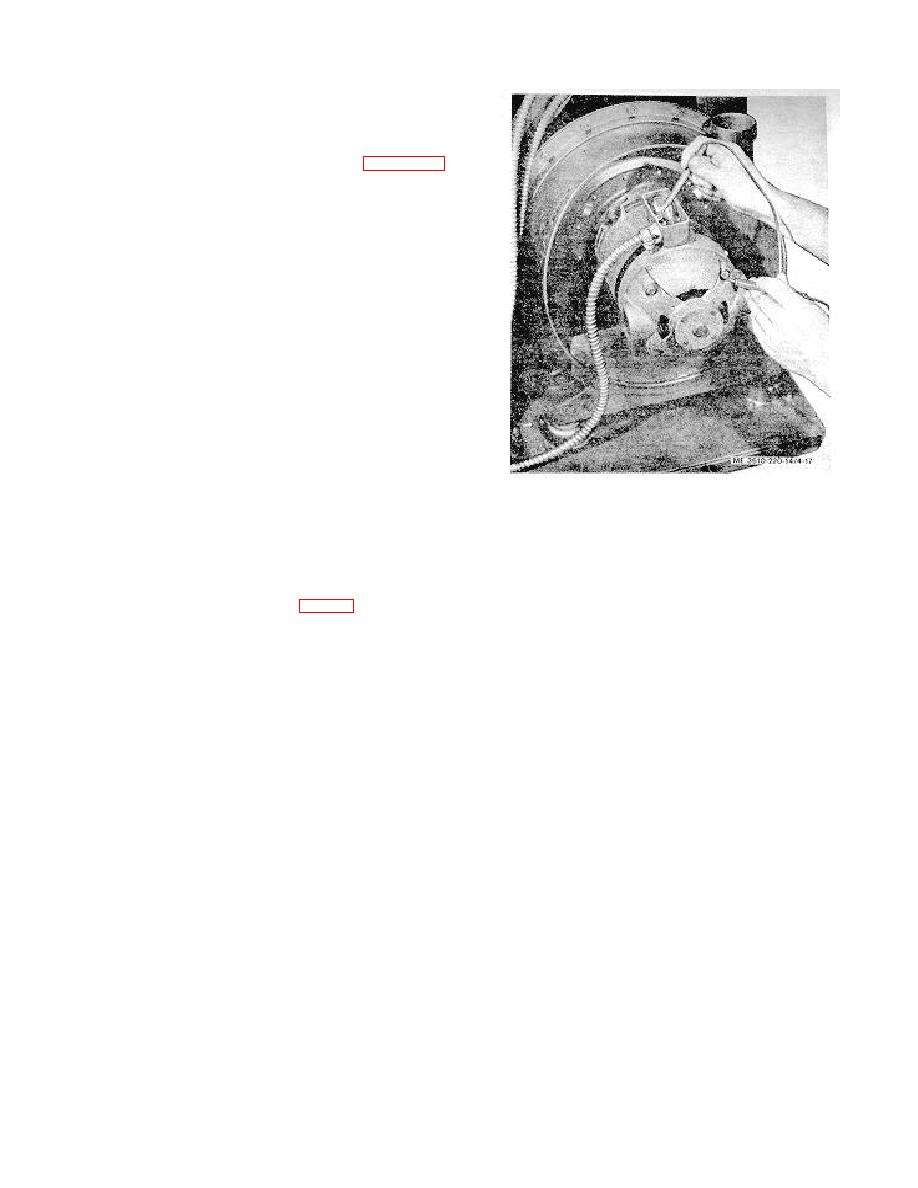

c. Testing of Short Circuit. Expose the terminal board in

outlet box of component in which shorting is occurring. Set the

switch control of the component to an ON position, theoretically

closing the circuit. Apply the test lead of test lamp to wire in

outlet box and the other test lead to the frame of component. If

shorting is present, the test lamp will not light. Figure 4-17

illustrates testing for short at turbo-compressor motor.

d. Repair and Replacement. Repair wire and cable with

electrical tape, wrapping neatly to avoid hum ping. Replace

conductors that have badly worn insulation or bare wire. Since

wires within the flexible cable are harnessed, the entire cable

must be replaced when defective conductors are present. The

wires housed inside the rigid cable are not harnessed and can

be individually replaced.

In removing short-circuited

conductors, attach new wire to defective wire on one end of

rigid cable and pull out defective wire from other end, replacing

it with a new wire. To replace broken wire in rigid cable,

remove broken segments. Wrap two new wires to end of good

wire in rigid cable. Pull this wire out from other end, replacing

the attached new wire in cable.

Figure 4-17. Testing for short circuit at turbo-

compressor motor.

Section IX. MAINTENANCE OF FOCUSING GLASS FRAME ASSEMBLY

4-34. Focusing Glass

c. Cleaning and Inspection. Clean the focusing glass with

a. Description. The focusing glass (7, fig. 2-4) is contained in

a soft, clean cloth dampened in acetone. Wipe all surfaces

the focusing glass frame by six holder clips (2 and 5) located on

thoroughly to keep focusing glass at maximum transparency.

the sides and bottom structures of the frame (4). The focusing

Dry the focusing glass with a soft, dry cloth. Clean the holder

glass is finished with a fine, uniformly grained surface which

clips with cleaning solvent and wipe parts dry with cloth.

contains a grid of photographically exposed, permanently fused

Inspect the holder clips for' bends and worn inner felt strip.

lines spaced at intervals of 0.100 inch and covering the 24by

Check clips with straight-edge forwarding. Replace defective

30-inch rated area. A clear transparent circle 1 inch in diameter

holder clip if necessary. Inspect the focusing glass for chipped

is provided in the center of the grid area on the focusing glass

edges affecting its alignment. Examine the glass for cracks and

and conforms with the optical axis of the camera.

breaks. Replace defective focusing glass.

b. Removal

d. Installation.

(1) Remove one of the bottom holder clips (2) on

(1) Install two side holder clips (5) on left side of

right side of focusing glass frame (4) by releasing four screws

focusing glass frame (4) with six screws (6).

(6).

(2) Install one bottom holder clip (2), retaining with

(2) Remove two side holder clips (5) on right side of

four screws (6). Do not tighten screw s.

focusing glass frame by removing three screws (6) on each.

(3) Position the focusing glass (7) on the focusing

(3) Supporting the focusing glass (7), loosen

glass frame under the holder clips.

screws on the remaining holder clips.

(4) Install the remaining two side holder clips (5)

(4)

Lift the focusing glass from its frame (4).

and the bottom holder clip (2) on the right side of focusing glass

(5) Release the remaining bottom holder clip and

frame. Retain with screws (6). Tighten screws on holder clips

the two side holder clips by removing screws.

previously installed.

4-20