missing screws and nuts. See that bellows are properly

supported by the tube support assembly, and that

internal reinforcement frames to which they are attached

are not bent or separated.

(5) Transparency holder assembly. Check

the transparency holder housing for dents and bends

affecting the inner components. See that the diffuser

glasses are properly seated in grooves. Check glasses

closely for scratches or other flaws within their work area

that will necessitate replacement. Examine the light box

assembly for broken ballasts and wire connections. See

that the light box slides smoothly into transparency

holder housing. Check the bolts and nuts, securing the

housing to the flange to assure that they are tight.

(6) Camera back assembly. Inspect the

camera back housing and its interconnecting members

for light-tight connections.

(7) Arc lamp assembly.

Examine the

reflectors and reflector doors of the arc lamps for bends

and tears. Check the carbon holders for missing or

damaged parts. Inspect the arm bracket castings

supporting the arc lamps for cracks and splits. Check

the wire connections of the transducer assembly located

in the arc lamp.

(8) Flash lamp assembly. Inspect the lamp

for broken outer glass. Check for burned-out bulb, Move

the flash lamp in a horizontal position to check operation

to lens. Check for loose wire connections and broken

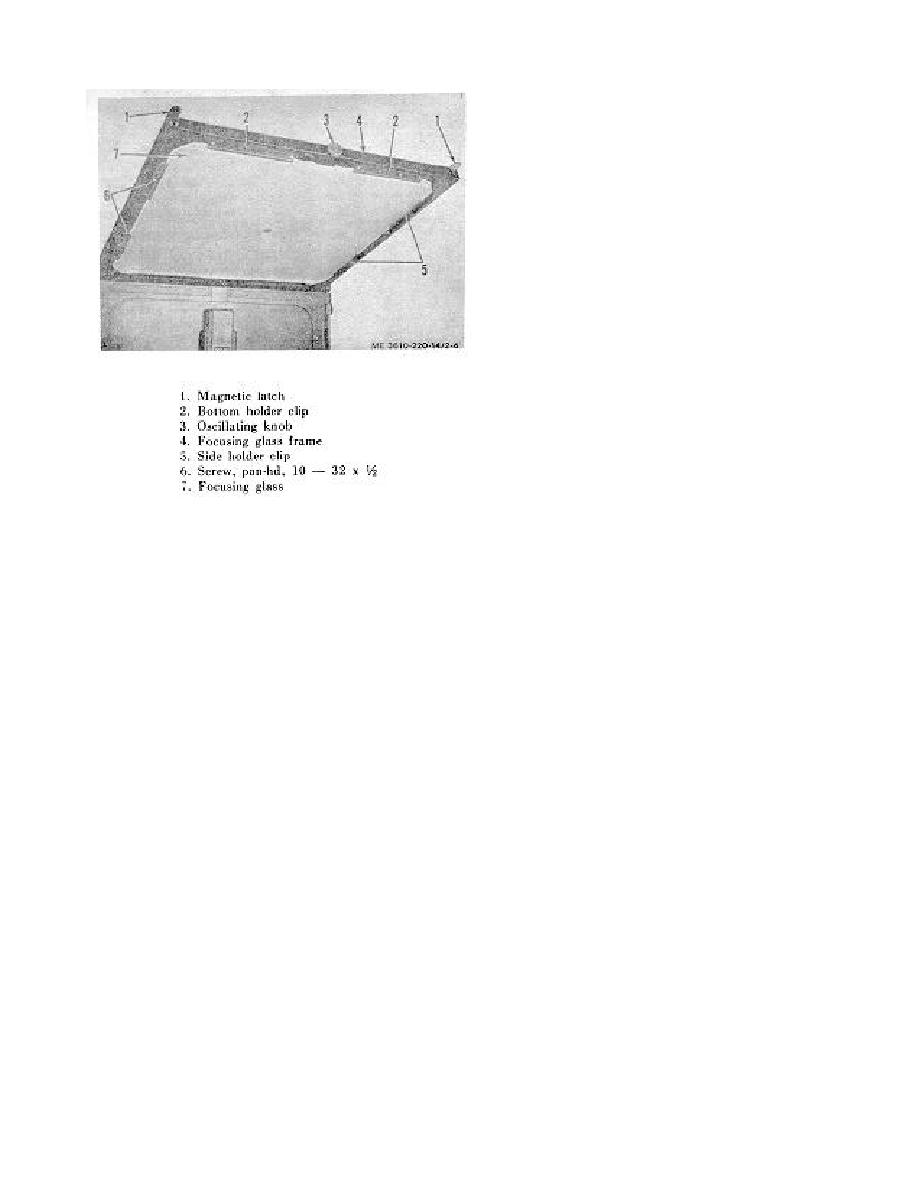

Figure 2-4. Focusing glass details.

wire plug and receptacle.

(9) Truss support assembly.

Check the

f. Inspection.

truss supports for breaks in casting. See that the truss

(1) General. Make a complete inspection of

supports are securely bolted to the skid platform and the

the copying camera, identifying the equipment and

support channel. Examine the cross members between

visually checking for loss and damage which may have

the truss supports for tight fit.

occurred in shipment.

(10) Copyboard

and

lensboard

drive

(2) Lensboard assembly.

Check the

mechanism. Check carefully for burred or damaged

lensboard carriage assembly for loosened bolts. Rock

threads on the drivescrews. Inspect the drive gears for

carriage assembly on rail to determine if carriage shoes

nicks and impacted dirt between the teeth. Examine the

and gibs have loosened from snug fit with the rail.

handwheels, gear guards, drive motors, and counters for

Inspect the inner lensboard frame and the shutter for

looseness, breaks, and other damage.

damage affecting their operation.

(11) Vacuum system. Check the flexible hose

(3) Copyboard assembly. Make a complete

to the vacuum back and copyboard for tears and

inspection of the copyboard for damages. Check the

improper connections. Examine the turbo-compressors

copyboard front and rear plates for warping. Inspect for

for dents in the housing or blockage of the mufflers that

missing or loosened screws. See that operating dial

might affect their function.

Check the vacuum

knob functions properly. Inspect the copyboard carriage

backhousing and the valve handle on the vacuum back

assembly for loosened bolts. Rock carriage assembly

for damage. Move the valve handle to several positions

on rail to determine if carriage shoes and gibs have

to see that it functions properly. Check the porous

loosened from a snug fit with the rail. Pivot the

suction plate for damage or injuries that may affect its

copyboard and transparency holder to determine if the

function.

axle and tube assembly binds or is difficult to move.

(12) Lubrication fittings.

Check the six

Inspect with thin feeler (0.0015 in. or 0.002 in.) between

lubricationfittings on the camera skid for looseness,

cop! board back and adjustable pads on base of

breaks, or other damage.

copyboard frames to ascertain if they contact uniformly

(13) Electrical system. Inspect all switches of

in both positions of the copyboard facing and away from

the camera for dismantling, damaged boxes, and loose

the lens).

wire connections. Check the wires and arc lamp cables

(4) Bellows assembly. Thoroughly inspect

for frayed or torn insulation. Examine all receptacles

the rubberized fabric for tears, cuts, or crack Check the

and cutout boxes for secure mounting.

end frames of the bellows for loose connections and

2-4