(6) Loosen screws (4) on the support bracket (1) to

d. Cleaning and Inspection. Clean all parts thoroughly

release the transformer. Lift the transformer from the support

with a cleaning solvent and clean cloth.

Dry the parts

bracket.

thoroughly with a soft cloth. Inspect hinge pins (4 and 8, fig. 4-

burrs around edge of bore. Inspect threads on hingepin shafts

c. Installation.

(4 and 8), pivot pin (12), and all screws for stripped or damaged

condition. Inspect locking bracket (13) for cracks and breaks.

Replace defective parts if necessary.

(1) Replace transformer on the support bracket (1,

e. Reassembly.

(2) Be sure the transformer (2) is firmly seated, and

then tighten screws (4, fig. 4-14).

(1) Drive pivot pin (12, fig. 4-12) into free end arm

(3) Insert cable wires through transformer panel

bracket (9). Position locking bracket (13) and secure with two

and attach the locknuts (2) to connector nipples (3).

screws (16). Insert remaining screw (14).

(4) Attach loose wires to mating terminals, and

(2) Position center arm bracket (7) and hinge it to

replace the transformer cover (3, fig. 4-13).

free-end arm bracket (9) with hinge pin (8). Secure hinge pin in

position with cap nut (18) onto threaded end of hingepin (8).

f. Installation.

Position center arm bracket (7) to

secured-end arm bracket (9, fig. 4-6). Insert hinge pin (4, fig. 4-

assembly (5, fig. 4-6) with washers (8) and secure with lock nut

(7). Replace washer (8) and cap nut (10) on underside of hinge

pin (6).

4-31. Transformer

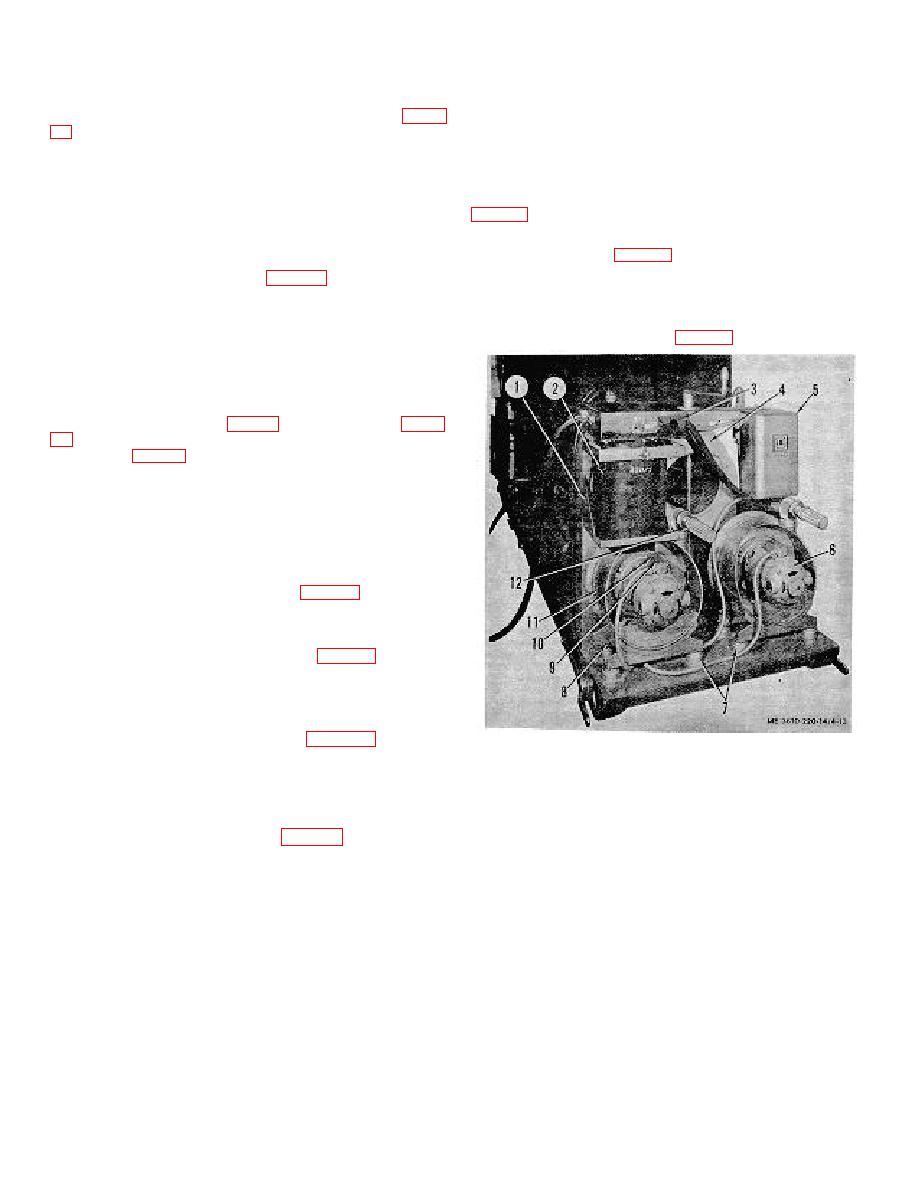

a. Description. The transformer used to supply the arc

lamps has a contactor-controlled primary input of 17 amperes

at 220 volts and a secondary output of 50 amperes at 30 to 50

volts to each lamp. The transformer (2, fig. 4-13) is located on

the copyboard end of the camera and is mounted on a bracket

(4) secured to the rear support plate (1). The transformer is

equipped with a cover (3) which, when removed, exposes the

terminal board connections and the wiring (fig. 4-14) connecting

the arc lamps and the external source cable.

b. Removal

(1) Remove the cover (3, fig. 4-13) from the

1. Support bracket

transformer (2) to make wire connections accessible.(2) Tab all

2. Transformer

wires coming from the cables using fig. i-11A for identification

3. Transformer cover

of wires and mating terminals.

4. Rear support plate

5. Magnetic contactor

(3)

Disconnect cable wires from terminals.

6. Vacuum back turbo-compressor assembly

7. Vibration mount

(4) Remove locknuts (2, fig. 4-14) from connector

8. Vibration mount nut

nipples (3). Dress wires to facilitate removing nipples.

9. Screw, rd hd, 10-32 x 3/4

(5) Remove cables from transformer, being

10. Outlet box cover

extremely careful not to snare wire insulation while pulling wires

11. Copyboard vacuum turbo-compressor assembly

through transformer panel.

12. Muffler

Figure 4-13. Camera components, copyboard end.

4-17