the slide bar (2, fig. 4-22) roller (1) and bearings (5). The slide

into flange of axle and tube assembly (1). Insert stud into

bars support the aerial film brackets; the rollers guide the film

bushing and screw stop nut (8) on stud.

over the polished glass diffuser; the cover frame clips hold the

(2) Position two valve guides (5, fig. 4-25) on

cover frame secure to the housing.

transparency holder housing (6), and secure each valve guide

with two screws (7), lockwashers (4), and nuts (3). Slide

b. Removal.

diverter valve plate (2) into tracks of valve guides.

(1) Remove the aerial film brackets from the slide

(3) Position four shims (4, fig. 4-26) as marked

bar (para 4-46. b. ).

during disassembly, and secure transparency holder housing

(2) Remove four screws (4, fig. 4-22), securing two

(5) to axle and tube assembly (1) with eight screws (6),

bearings (5) to transparency holder housing (10), one at each

lockwashers (3), and nuts (2).

end of roller ( 1 ). Remove roller, bearings, and roller spacers

(4) Working through port of transparency holder

(9).

housing, slide diverter valve plate (2, fig. 425) to +he left and

(3) Remove two screws (6) from each of two cover

secure diverter plate to stud (10) with stop nut (8).

frame clips (7). Remove clips and clip spacers (8).

(5) Install the diffusers and light box assembly

(4) Remove 14 screws (3), securing slide bar (2) to

(para 4-47. d. ).

transparency holder housing (10). Lift off bar.

4-50. Aerial Film Mounting Attachments

a. Description. Two groups of aerial film mounting

attachments are provided on the transparency holder housing,

each group having identical parts. The attachments consist of

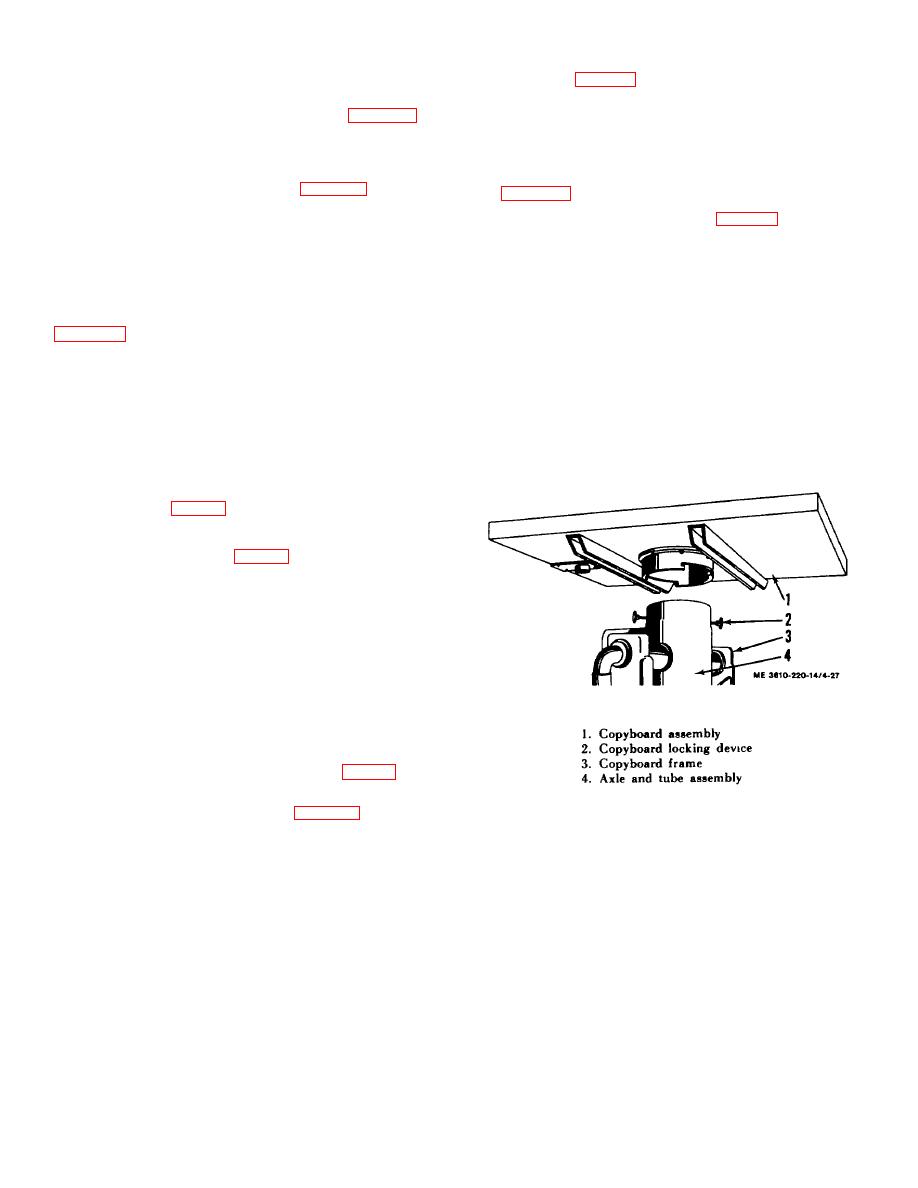

Section XIV. MAINTENANCE OF COPYBOARD ASSEMBLY AND

COPYBOARD LOCKING DEVICE

4-51. Description

The copyboard (5, fig. 1-6) is mounted on the axle and tube

assembly (3) by two hand knobs (6) which are part of the

copyboard locking devices. The locking devices fit into the slots

of the copyboard flange (4, fig. 1-6), holding the copyboard

secure. The flange is bolted to the copyboard, providing a rigid

interconnection of the assemblies.

4-52. Copyboard Assembly

a. Description.

The front surface of the copyboard

assembly contains a series of inlet holes systematically

arranged to hold copy of specified sizes. The operating knob

(7) on the back of the copyboard controls the suction area of

the assembly.

b. Removal.

(1) Loosen the two hand knobs (6, fig. 1-6) on the

axle and tube assembly (3).

(2) Turn the copyboard (1, fig. 4-27) clockwise to

Figure 4-27. Copyboard assembly, exploded view.

free the locking devices (2) from the slots of the copyboard

flange. Lift the copyboard from the axle and tube assembly (4),

c. Cleaning and Inspection. Clean the surfaces of the

oscillating it slightly to assist its release. Be extremely careful

copyboard with a clean cloth dampened with cleaning solvent.

not to damage copyboard.

Clean clogged inlet holes on the front plate of the copyboard.

Dry surfaces thoroughly with a clean cloth. Inspect the front

plate for damaged surface, cracking, and corrosion.

4-29