CHAPTER 5

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

5-2. Tools and Equipment

5-1. General

Instructions in this section and in succeeding sections of this

a. The operations detailed in this chapter may be

chapter are published for the use of maintenance personnel

performed with standard mechanic's hand tools.

responsible for general support and higher levels of

b. Repair parts and equipment are listed and illustrated in

maintenance of the copying camera. They contain information

the repair parts and special tools list covering direct and general

on maintenance which is beyond the scope of the tools,

support maintenance in TM 5-3610-220-35P.

equipment, or supplies normally available to using

organizations.

Section II. TROUBLESHOOTING

The possible remedy recommended is described opposite the

5-3. Use of This Section

probable cause.

This section provides information useful in the diagnosing and

correction of unsatisfactory operation or failure of the copying

camera or any of its components. Each trouble symptom

stated is followed by a list of probable causes of the trouble.

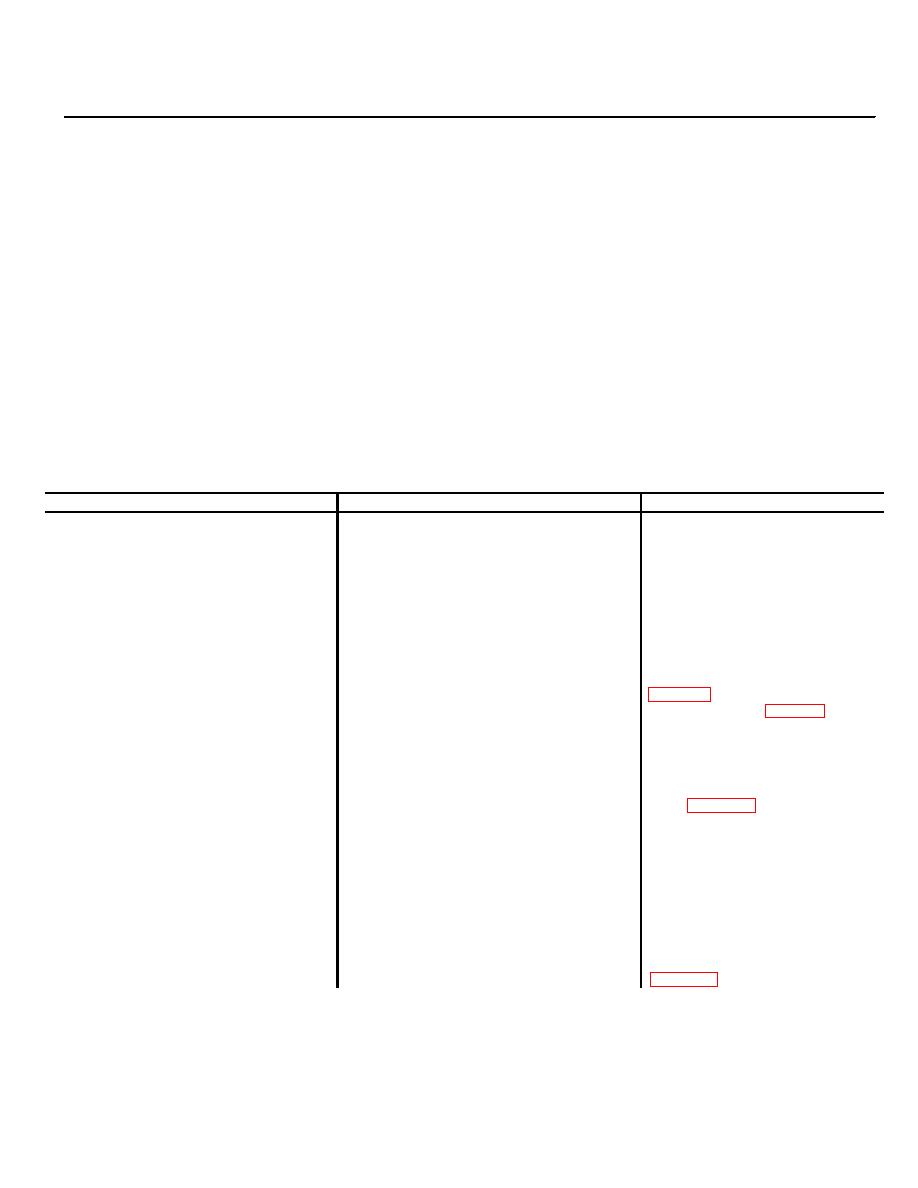

Table 5-1. Troubleshooting

Malfunction

Probable Cause

Corrective Action

1. Vacuum back fails to hold film properly

a. Improper selection of vacuum back valve

a. Measure size of film and move

ports.

valve handle to a position best suited

to hold film on vacuum back.

b. Opening in vacuum flexible hose.

b. Remove hose clamps at the

vacuum back valve housing and

suction pipe on camera skid, and

remove flexible hose. If opening in

hose is comparatively small, make a

temporary repair with electrical tape.

c. Vacuum turbo-compressor defective.

c. Replace defective parts of

vacuum turbo-compressor assembly

compressor motor (para 6-6).

Replace entire unit if necessary.

2. Copyboard fails to hold copy properly

a. Copyboard suction not directed properly.

a. Measure size of copy and turn

operating knob to the correct

position.

b. Operating gate out of line.

b. Align operating gate on operating

shaft (para 6-16. a. ).

c. Diverter valve plate not in closed position.

c. Diverter valve plate is in open

position, permitting suction to the

transparency holder and thereby

lessening the vacuum to the

copyboard. Push the diverter knob

completely in.

d. Clogged suction holes in copyboard.

d.

Foreign matter in holes of

copyboard causes and unequal

distribution of suction.

Remove

copyboard front plate and clean

5-1