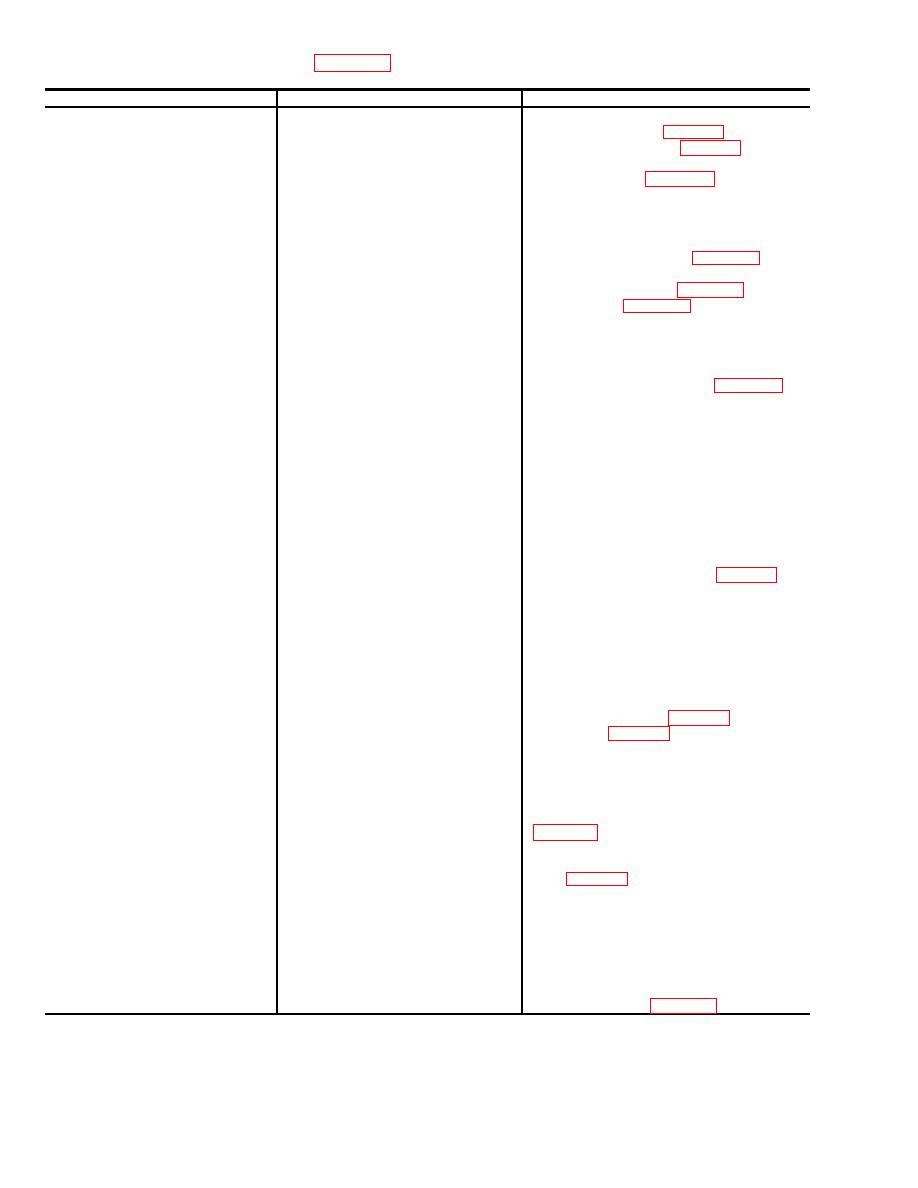

Table 5-1. Troubleshooting-Continued

Malfunction

Probable Cause

Corrective Action

e. Vacuum turbo-compressor

e. Replace defective parts of vacuum turbo-

defective.

compressor assembly para 6-2) or vacuum

turbo-compressor motor (para 6-6).

Replace entire unit if necessary.

3. Arc lamp flickers

a. Gap between carbons too great

a. Adjust carbons (para 4-27. d.).

to provide consistent lighting.

b. Drafty conditions around operating

b. Eliminate all drafts around working area

location.

of cameras.

c. Carbons of different lengths in

c. Substitute carbons of same length or

holders.

replace with new carbons (para 4-27. a. ).

d. Contacts in magnetic contactor

d. Smooth badly pitted or burned

not making proper contact.

contacts with a fine file (para 6-36). Replace

defective parts (para 6-36) if necessary.

e. Defective sensing device.

e. If one lamp does not flicker, switch the

cables from the operating lamp sensing

device to suspected sensing device. If the

lamp which did not flicker now does, replace

the defective sensing device. ( ara 6-37 )

4. Image distortion

a.

Copyboard not aligned with

a. Trammel four corners of copyboard with

focusing glass.

focusing glass for correct alignment of

components. Check that focusing glass

frame is firmly contacting at magnetic

latches on both sides of frame

b. Lens not positioned correctly.

b. Check

the lensboard

counter

readings. Determine if lens is screwed in

the lens plate.

c. Copy not placed on copyboard

c. Remove copy and remount on

properly.

copyboard, smoothing out wrinkles and

folds.

d. Lensboard or copyboard

d. Recalibrate camera to lens (para 5-5).

positioning counters not calibrated to

lens.

e. Distance of lensboard not related

e. Recheck the focusing Chart for correct

to same reduction ratio.

lensboard and copyboard distance.

f. Thick copy.

f. If copy has appreciable thickness, its

thickness must be added to the copyboard

counter readings in units of 1/100 inch.

5. Vibration or excessive noise

a. Impeller plates in vacuum turbo

a. Remove the vacuum turbo-

during operation

compressor not positioned properly.

compressor assembly (para 6-2.a. ),

disassemble (para 6-2. a. ), and reset the

impeller plates.

b.

Dry oil felt wipers causing

b.

Apply

oil to wipers.

Let the oil

lensboard or copyboard to vibrate

penetrate thoroughly before resuming

while under power.

operation.

c. Compressor fan in turbo-

c. Align compressor fan on motor shaft

compressor motor rubbing against

(para 6-8. a.)

rear end frame.

d. Dry or burned-out bearings in

d. Replace defective bearings with new

turbo- compressor motors or drive

ones (para 6-8. a. and 6-12. a. ).

motors.

e. Loose mounting hardware.

e. Locate loose hardware and tighten.

f. Gear meshing.

f. Vibration or noise will result if drive gears

are not fully meshed. If gears are dry, apply

sufficient grease, or if foreign matter is

impacted between the teeth, clean

thoroughly, or if a tooth is damaged, dress

off or replace gear (para 6-32. a.)

5-2