6-27. Lensboard Carriage Cleaning and

Inspection

Clean all parts thoroughly with a cleaning solvent, using a small

brush to clean threaded areas. Inspect frames for splits,

cracks, and distortion. Replace if defective. Inspect carriage

base plate for cracks and splits. Inspect all threaded areas for

stripped or dam aged condition. Inspect gibe and shims for

scoring or wear and gears for damaged teeth. Replace all

defective parts.

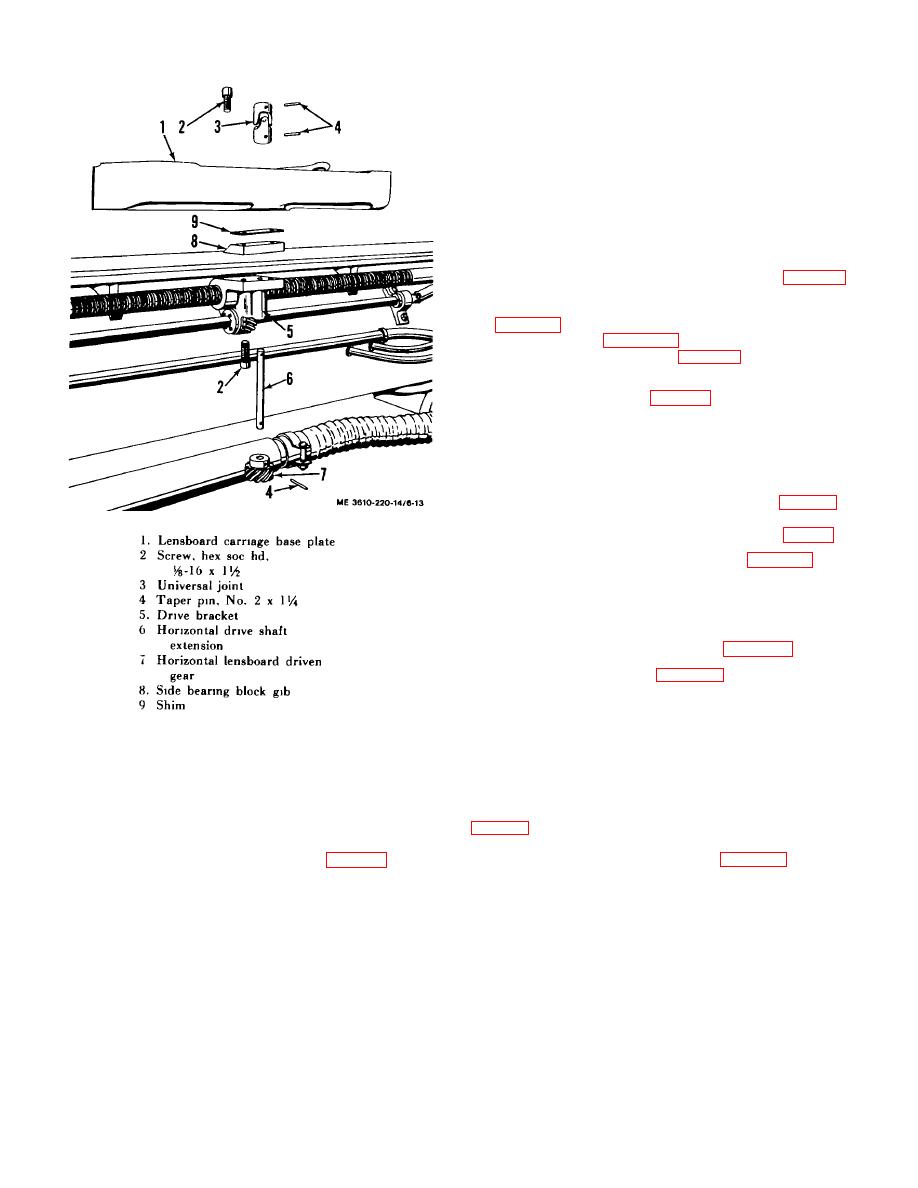

6-28. Lensboard Carriage Reassembly

camera rail, and line up four side bearing gibe (8) and shims

(9). Secure each gib to carriage base plate with eight screws

(5, fig. 6-12). Take up play between gibe and rail, as with

copyboard carriage (para 6-20. b. (1))-. Position carriage

base plate and drive bracket (5, fig. 6-13), and secure bracket

to base plate with two screws (2).

extension (6), and lock on extension with tapered pin (4). Slide

extension assembly through drive bracket (5) and base plate

(1), and attach universal joint (3) to extension with tapered pin

(4). Install vertical drive shaft extension and driven gear on

other side of base plate in the same manner.

wiper guards (14), and secure each to carriage base plate (17)

with two screws (15). Install two limit switches (10, fig. 1-5).

carriage base plate (6). Insert pins (3) and align holes. Insert

two lockwashers (1) and hex socket head screws (2), and tap

pin (3) into place. Install the side frame (a) in the same

manner.

Figure 6-13. Lensboard carriage base plate, exploded

view.

Section VIII. CAMERA DRIVE MECHANISM

pinned to the drive-screw (12 and 13). A handwheel (7 and 9,

6-29. Description

The copyboard drive mechanism and the lensboard drive

counter drive sprocket is connected to the positioning counter

mechanism are identical systems. The data in this section are

by a counter drive chain (4 and 6, fig. 6-14). The drive

applicable to either unit. A gear (1 and 10, fig. 6-14) mounted

mechanism is disassembled on its removal.

on the drive motor shaft is meshed with a gear keyed and

6-13