operating gear and shaft (19-. Position cover plate (5) and

(b) Position block (4) on operating rod

secure with eight screws (6). Position operating dial plate (18)

and secure with two screws (31.

and secure with four screws (7-. Slide operating knob (17) on

operating gear and shaft (19) with indicator on operating knob

rod recesses and insert hex socket head screw (9) through

pointing to the smallest setting on operating dial plate. Secure

bottom of rod. Tighten hex socket head screw until step in tooth

operating knob to shaft dial plate. Secure operating knob to

is flush with edge of beveled recess. Install the remaining two

shaft with setscrew (8).

teeth in the same manner.

(7) Position copyboard flange (9, fig. 6-6) and

(d) Position operating rod rack (1) in

secure to copyboard back plate assembly (1) with eight screws

operating rod recess and secure with three hex socket head

(2, fig. 6-5), lockwashers (10, fig. 6-6), and nuts (15). Position

screws (10).

copyboard front plate (6, fig. 6-5) and secure with 88 screws

(7).

(5) Position operating rod assembly (3, fig. 6-6) in

its extreme right-hand position. Engage innermost operating

(8) Position two copyboard cross braces (16,

gear so that it meshes with the first tooth on the operating rod

assembly. With tooth and rod in this position, pivot operating

(11) onto stud (l 2) and screw into copyboard. Turn nut (14)

gate until it is 45 from the closed position. Tighten the

onto protruding stud and seat stud on back of cross braces

previously installed operating gear setscrew (8). In similar

(16). While holding one nut (14) tighten second nut (14) to lock

manner, set the remaining two operating gears and gates.

stud in seated position. In similar manner, install remaining It

Install operating rod stop screw (2).

studs (12) in cross braces.

(6) Push operating rod (3, fig. 6-6 (to the extreme

right-hand position. This will close all operating gates. Insert

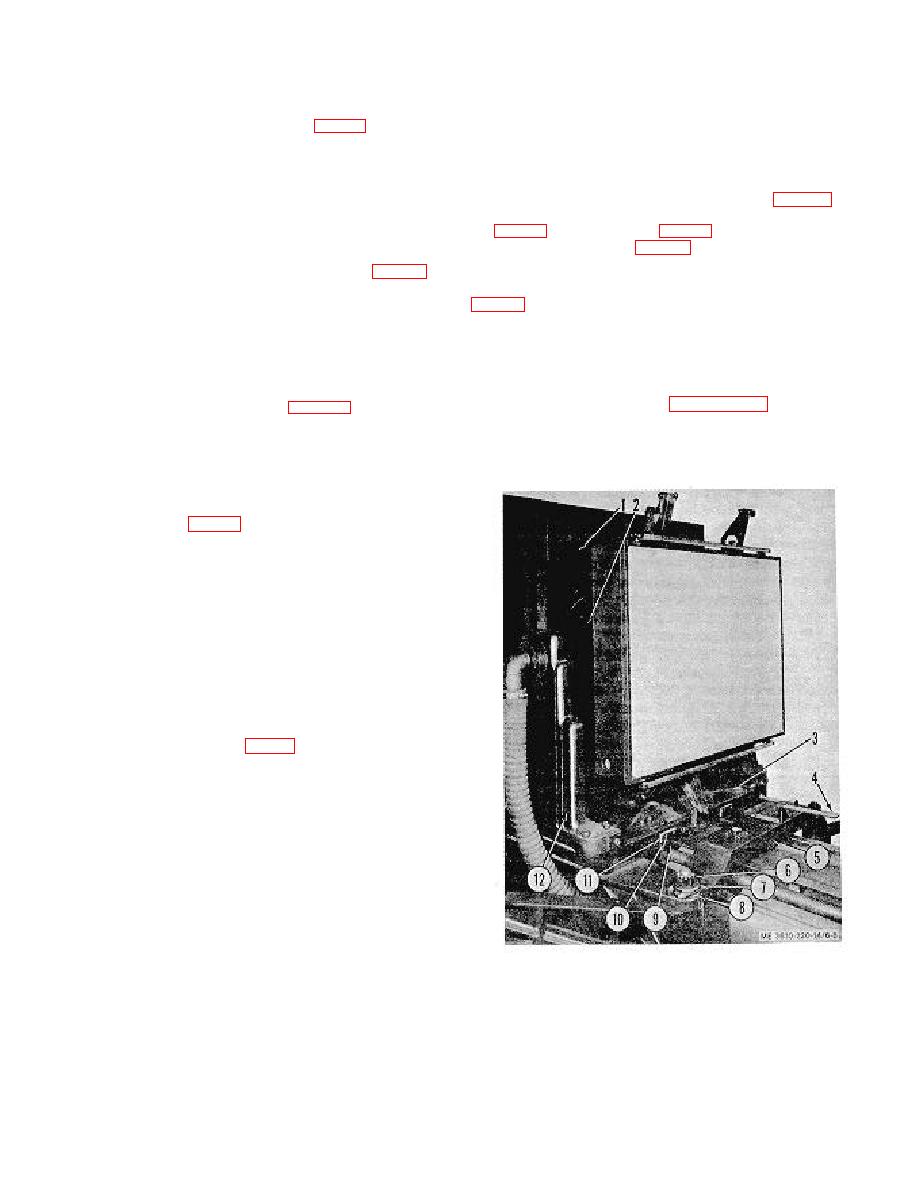

Section V. COPYBOARD CARRIAGE ASSEMBLY

6-17. Description

The copyboard carriage assembly consists primarily of the axle

and tube assembly (2, fig. 6-8), copyboard frames (12), and the

carriage base plate (3-. The copyboard assembly is secured to

the axle and tube assembly which is able to swing through a

180arc. A drivescrew moves the entire copyboard carriage

assembly backward or forward on the camera rail. The axle and

tube assembly is supported by the two frames (12) and rotates

freely between them on its axle. The frames in turn are each

bolted and pinned to the carriage base plate for rigidity. Two

brackets (8) for mounting the arc lamp arm brackets are

secured to the carriage base plate. A cross brace assembly (5)

with internal rollers rides on the camera rail and offsets the

weight of the arm brackets and arc lamps. A limit switch bracket

(4) is mounted on top to limit travel of the assembly.

KEY to fig. 6-8:

1. Copyboard assembly

2. Axle and tube assembly

3. Copyboard carriage base plate

4. Limit switch bracket

5. Cross brace assembly

6. Hinge pin nut

7. Washer

8. Secured-end arm bracket

9. Wiper guard

10. Screw, hex soc kid, 10-

32 x 3/4

11. Oil felt wiper

12. Copyboard frame

Figure 6-8. Copyboard carriage assembly, installed.

6-8