TM 5-3610-220-14

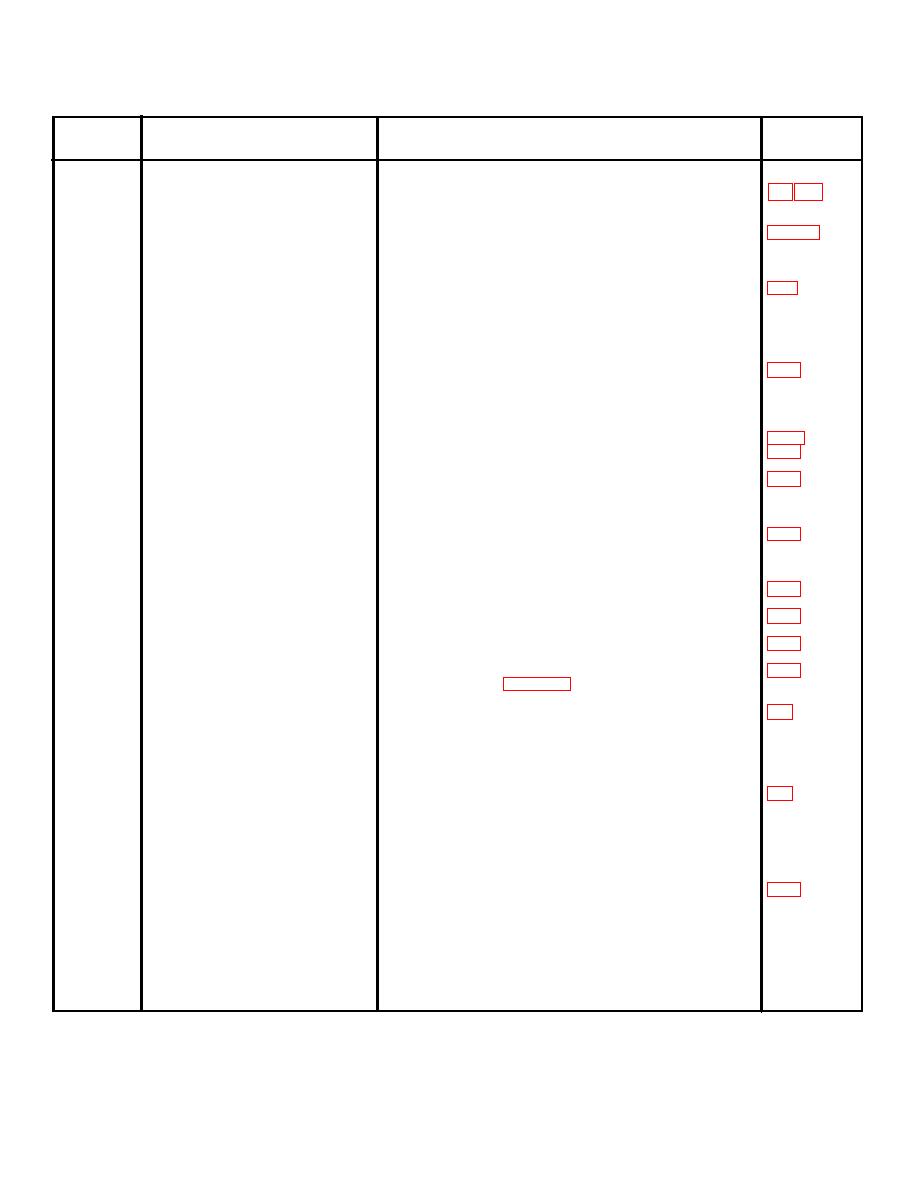

Table 4-1. Preventive Maintenance Checks and Services

Organizational Maintenance Category

Monthly Schedule

Sequence

Item to be

Paragraph

number

inspected

Procedure

reference

1.

Lubrication

Lubricate if necessary.

2.

Tools and equipment

See that all tools and equipment assigned to the camera

are clean, serviceable, and properly stowed in toolbox.

See that tool box is in good condition and that it closes

and fastens properly.

3.

Wiring, switches

Inspect wiring for oil-soaked, cracked, or frayed in-

sulation, broken wires and cables, and loose or

corroded connections. Check operation of switches.

2-1. f. (13)

Replace defective switches and wires. See that all

wiring is clean and that connections are clean and

tight.

4.

Magnetic contactor

Check the magnetic contactor for secure mounting and

tight wire connections. See that contact points make

contact and are flush. Check wires for shorting.

Tighten or replace all loose or missing screws. Replace

defective wires.

5.

Arc lamps

Replace defective or short carbons. Adjust gap between

carbon ends for correct spacing, if necessary. Clean

ash from bottom of arc lamp. Repair or report any

breaks or cracks in arc lamp exterior.

6.

Copyboard and lensboard

Inspect drive gears for proper setting and mesh. Check

transmission

for any unusual gear noise during operation. Check

gears for wear. If gears are worn or unusual noises are

present, report condition to the proper authority.

7.

Counter sprockets and chains

Check the counter sprockets for wear and damage.

Check the chains for wear, loose or missing links, and

proper tension. Repair or replace worn or damaged

chains.

8.

Universal joints

Check universal joints for wear and damage. Check for

loose or missing pins, holding joints to shafts. Replace

worn or damaged universal joints and loose or missing

thru

pins.

9.

Copyboard and lensboard

Check the drivescrews for damaged threads. Inspect the

drivescrews

drivescrews for end play at the end supports of the

camera. See that worn or damaged drivescrews are

thru

repaired or replaced. Adjust drivescrews if end play is

beyond limitations (para 6-32. b.).

10.

Turbo-compressors

Check the mounting of the turbo-compressors on the

vibration mounts and against the frame of the camera.

Check for suction. Tighten or replace loose or missing

mounting bolts and nuts; replace worn vibration

mounts. Report condition to proper authority if poor

suction exists.

11.

Turbo-compressor

Tighten or replace loose or missing mounting bolts and

nuts. If unusual noises exist due to friction of parts,

report condition to the proper authority. Replace

brushes that are worn beyond limits or brushes with

weak springs. Tighten wire connections securely. Be

sure that brushes are free in the holders for proper

contact with commutator.

12.

Lensboard assembly

Tighten all loose connections and replace missing bolts

and nuts. Replace worn wipers on the carriage with

new, oiled wipers; tighten the wiper guards. If

carriage gibs are worn, causing faulty reproduction,

report condition to the proper authority. Faulty or

damaged vertical and horizontal drive shafts,

preventing proper movement of inner lensboard

frame, must be reported to the proper authority.

Replace weak or damaged inner lensboard frame

spring. Report unsatisfactory operation of shutter.

4-2