TM 5-3610-220-14

Section IV. TROUBLESHOOTING

stated is followed by a list of probable causes of the trouble.

3-7. Use of Troubleshooting Section

The possible remedy recommended is described opposite the

This section provides information useful in diagnosing and

probable cause.

correcting unsatisfactory operation or failure of the copying

camera or any of its components. Each trouble sympton

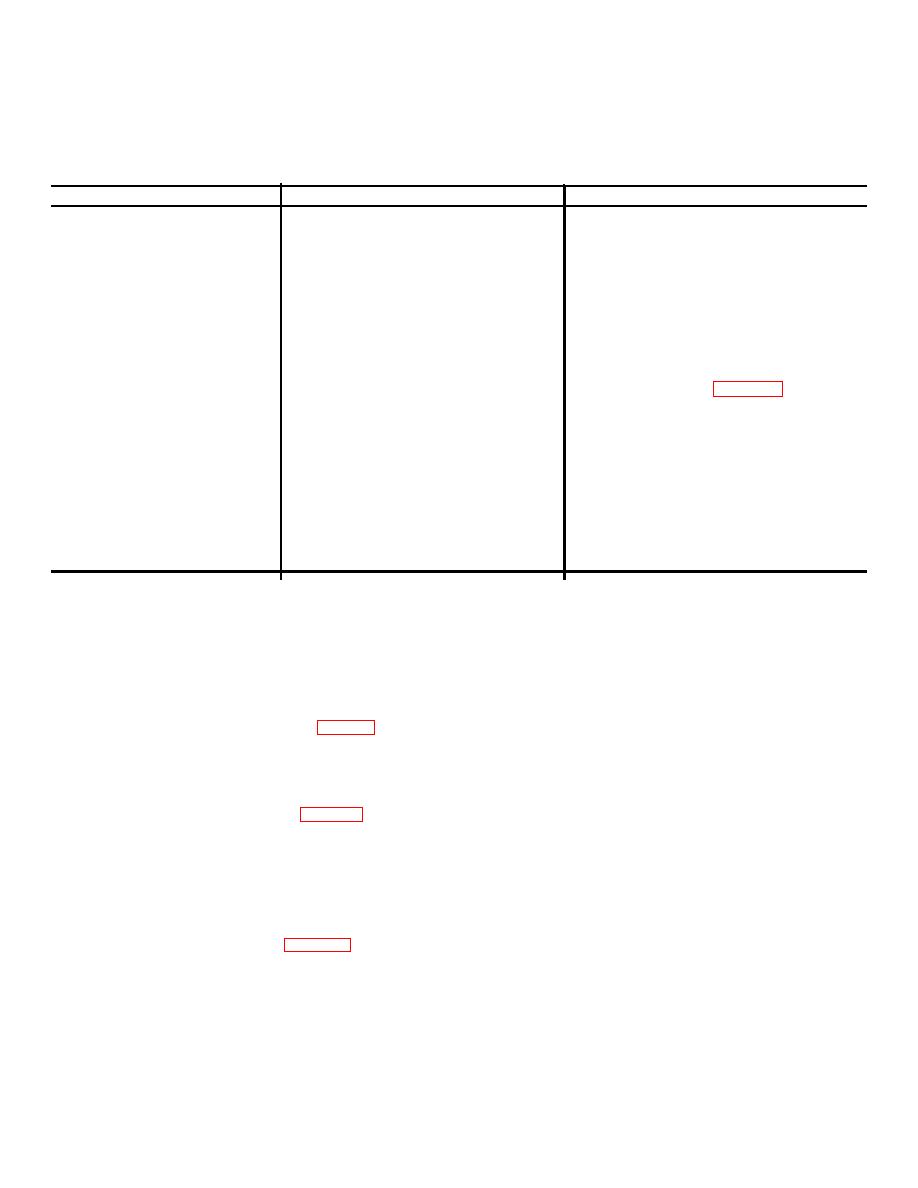

Table 3-2. Troubleshooting

Malfunction

Probable Cause

Corrective Action

1. Vacuum back fails to hold film

a. Improper selection of vacuum back

a. Measure size of film and move valve

properly.

valve ports.

handle to a position best suited to

hold film of vacuum back.

b. Opening in vacuum flexible hose.

b. If opening is small make temporary

repair with electrical tape. Notify

proper authority for permanent

repair.

2. Copyboard fails to hold copy

Copyboard suction not directed

Measure size of copy and turn

properly.

properly.

operating knob to correct position.

3. Arc lamps flicker.

a. Drafty conditions around operating

a. Eliminate all drafts around working

location.

area.

b. Gap between carbons too great to

b. Adjust carbons. (para 4-27)

provide constant lighting.

4. Image distortion.

a. Thick copy.

a. If copy has appreciable thickness, its

thickness must be added to the copy-

board counter readings in units of

1 / 100 inch.

b. Copy not placed on copyboard

b. Remove copy and remount on

properly.

copyboard, smoothing out wrinkles

and folds.

c. Lens not positioned.

c. Check the lensboard counter

readings. Determine if the lens is

screwed in the lens plate.

Section V. MAINTENANCE OF VACUUM TURBO-COMPRESSOR ASSEMBLY

3-8. General

3-9. Maintenance and Adjustment

The vacuum for the operation of the vacuum back and the

The mountings of the turbo-compressor should be inspected

copyboard is provided by two separate but identical vacuum

for loose or worn fittings, and the turbo-compressor inspected

turbo-compressors. The compressors are located at the

for suction. If there are any discrepancies, they should be

extreme copyboard end of the camera, and are mounted

reported to the proper authority.

separately. Each turbo-compressor is mounted on four

vibration mounts bolted to the camera skid (para 1-3 h).

Section VI. MAINTENANCE OF LENS ASSEMBLY

counterclockwise direction to unlock the lens (5) from the

3-10. Lens, 19 Inch

inner lensboard frame (4).

apochromat Artar lens equipped with an attached mounting

(2) Release the lens mounting plate and the lens

plate (4) and a lens cap (3). The diaphragm opening control

from the slots of the inner lensboard frame.

(5), integral with the lens is mounted on the lens barrel. A

c. Cleaning and Inspection. Always keep lens covered

special lens box (2) is provided to store the lens when it is not

when not in use. Avoid touching lens surfaces. Clean only if

mounted on the camera.

accumulated dust or accidental fingerprints necessitate it. To

b. Removal

clean, first dust with a clean camel's hair brush. If markings

(1) Grasp the knobs (3, fig. 2-11) on the lens

mounting plate (2), and rotate 15 degrees in a

3-5