TM 5-3610-220-14

Section V. TROUBLESHOOTING

4-9. General

Each trouble symptom stated is followed by probable causes

This section provides information useful in diagnosing and

of the trouble.

The possible remedy recommended is

correcting unsatisfactory operation or failure of the copying

described opposite the probable cause.

camera or its components.

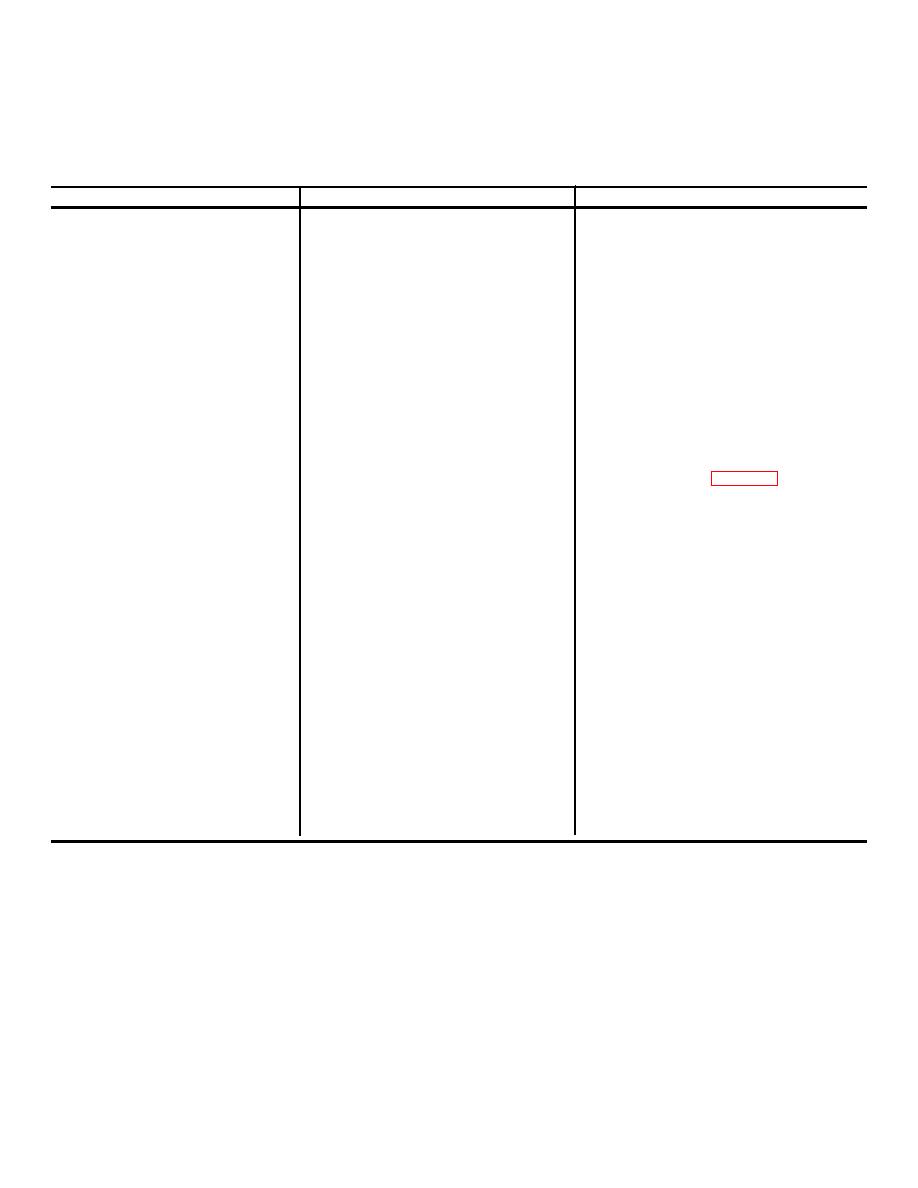

Table 4-2. Troubleshooting

Malfunction

Probable Cause

Corrective Action

1. Vacuum back fails to hold film

a. Improper selection of vacuum back

a. Measure size of film and move valve

properly

valve ports

handle to a position best suited to

hold film on vacuum back.

b. Opening in vacuum flexible hose

b. Remove hose clamps at the vacuum

back valve housing and suction pipe

on camera skid, and remove flexible

hose. If opening in hose is com-

paratively small, make a temporary

repair with electrical tape.

2. Copyboard fails to hold copy properly

a. Copyboard suction not directed

a. Measure size of copy and turn

properly.

operating knob to the correct

position.

b. Diverter valve plate not in closed

b. Diverter valve plate is in open

position.

position, permitting suction to the

transparency holder and thereby

lessening the vacuum to the

copyboard. Push the diverter knob

completely in.

3. Arc lamps flicker

a. Gap between carbons too great to

a. Adjust carbons (par. 4-27. d.).

provide consistant lighting.

b. Drafty conditions around operating

b. Eliminate all drafts around working

location.

area of camera.

4. Image distortion

a. Copyboard Not aligned with focusing

a. Trammel four corners of copyboard

glass

with focusing glass for correct

alignment of components. Check

that focusing glass frame is firmly

contacting at magnetic latches on

both sides of frame.

b. Lens not positioned correctly.

b. Check the lensboard counter

readings. Determine if lens is

screwed in the lens plate.

c. Copy not placed on copyboard

c. Remove copy and remount on

properly.

copyboard, smoothing out wrinkles

and folds.

d. Distance of lensboard not related to

d. Recheck the focusing chart for

same reduction ratio.

correct lensboard and copyboard

distance.

e. Thick copy.

e. If copy has appreciable thickness, its

thickness must be added to the

copyboard counter readings in units

of 1/ 100 inch.

5. Vibration or excessive noise during

a. Dry oil felt wipers causing lensboard

a. Apply oil to wipers. Let the oil

operation

or copyboard to vibrate while under

penetrate thoroughly before

power.

resuming operation.

b. Loose mounting hardware.

b. Locate loose hardware and tighten.

4-4