6-44. Camera Rail, Tube, and Drivescrew Cleaning and

(4) Install the camera back by connecting back

Inspection

support plate (4, fig. 6-17) to tube flange by inserting eight hex

Clean the tube and its front and rear flanges with a brush and

socket head screws (3) and lock-washers (21. Clamp flexible

cleaning solvent. Clean the camera rail and drivescrews and

rubber hose (12, fig. 1-4) onto vacuum back valve housing (1).

jack screws with a cloth dampened with cleaning solvent.

(5) Install the truss support assemblies (para 6-41)

Clean out dirt impacted in teeth of drive sprocket and between

at both ends of camera.

links of drive chain. Brush off dirt on camera skid, and then

clean with a brush and cleaning solvent. Inspect the tube for

(6) Screw on copyboard and lensboard drive

dents and damages, affecting its alinement. Check the tube

brackets on the drivescrew. Insert shaft end of drivescrew into

flanges for cracks and splits in casting. Inspect the rail's bevel

front tube flange (13, fig. 6-17); insert other end into flange (14,

edges for wear and corrosion. Examine drivescrews and jack

screws for slipped or worn threads and for general wear,

procedure.

affecting their alignment. Check the drive sprockets for broken

(7) Connect lensboard extension shaft (10, fig. 6-

or worn teeth, and the drive chain for damaged links. Replace

defective parts if necessary. Lubricate the drivescrews and jack

universal joint (12). In similar manner, connect extension shaft

screw s.

on other side of rail (5).

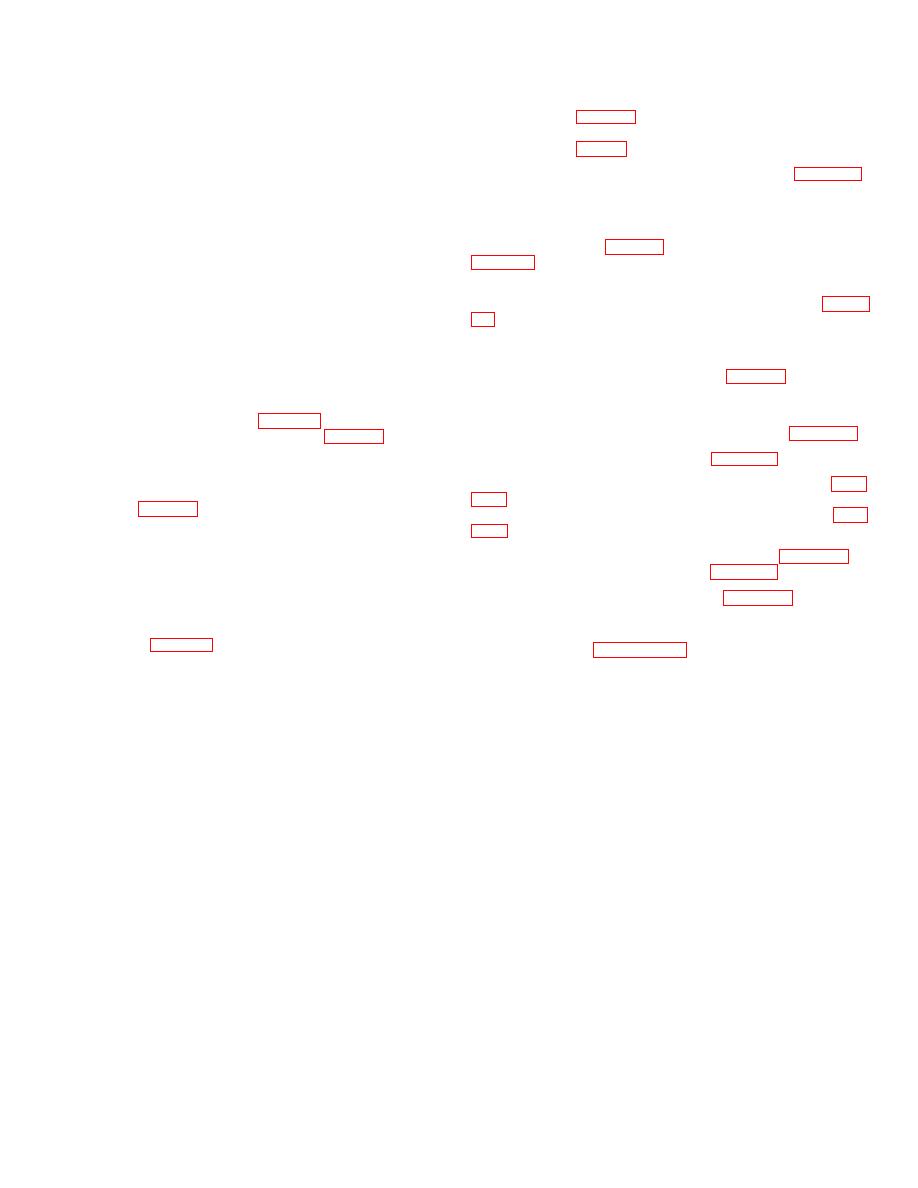

6-45. Camera Rail, Tube, and Drivescrew Installation

(8) Install the camera rail (7, fig. 6-19) on the tube

a. Installation.

(12) with 26 screws (8). Install limit switch track (9) with six

(1) Place and align the tube on the camera skid.

screws (10).

Screw the front jack screw (14, fig. 6-17) into the front tube

(9)

Install the camera drive mechanism (para 6-32).

flange (131, and the rear jack screw (13, fig. 6-19) into tube

flange (14). Block up or hoist the camera tube to allow for

(10)

Install the drive motors (para 4-44. d. ).

installation of drive chain and sprockets.

(11) Install the copyboard carriage assembly (para

(2) With the camera tube suitably raised, lower the

jack screw (2, fig. 6-21) until it protrudes through bottom of tube

the arc lamp arm assembly on the copyboard carriage (para

flange. Place the drive sprocket (6) on jack screw and secure

4-30. f. -.

with tapered pin (7) and setscrew (10-. Lower the jack screw

(12) Attach the bellows to the camera (para 4-37. d.

until its end rests in bearing (9) on camera skid. In the same

(and install the tube support assembly (para 4-36. d. ).

manner, install other jack screw at opposite end of camera.

(13

Install thefocusing glass (para 4-34. d. ).

(3) Adjust the jack screws so as to provide a

uniform lift with each other. Turn jack screws individually,

counterclockwise or clockwise, to obtain correct adjustment.

b. Calibrating. Calibrate the camera to the lens as

Install chain (5, fig. 6-21) on drive sprockets (6l, being careful

detailed in paragraph 5-5.

not to turn jack screws.

6-20