TM 11-7025-210-23

(5) The solenoid plunger enters a hole in the top member of the coil bar. The bottom portion of the coil bar

has a threaded hole to receive a threaded solenoid pole piece. The penetration of the pole piece in the coil bar is

adjustable, and its position or depth is secured by a locking nut. This allows a travel adjustment of the upper plunger. The

timing process of activating a hammer is effected by the photocell position. The time from coil energization to hammer

strike is approximately 1.3 milliseconds. When the hammer is at rest, it is held against the hammer backstop bracket by

the hammer return spring.

(6) A narrow belt which rotates about a second set of pulleys directly on top of the print belt pulleys serves

as a traveling rebound belt for the print fingers. The traveling rebound belt and the rebound bar act as a stop for a type

finger after a character has been printed. This prevents the type fingers from oscillating and snagging on the hammers.

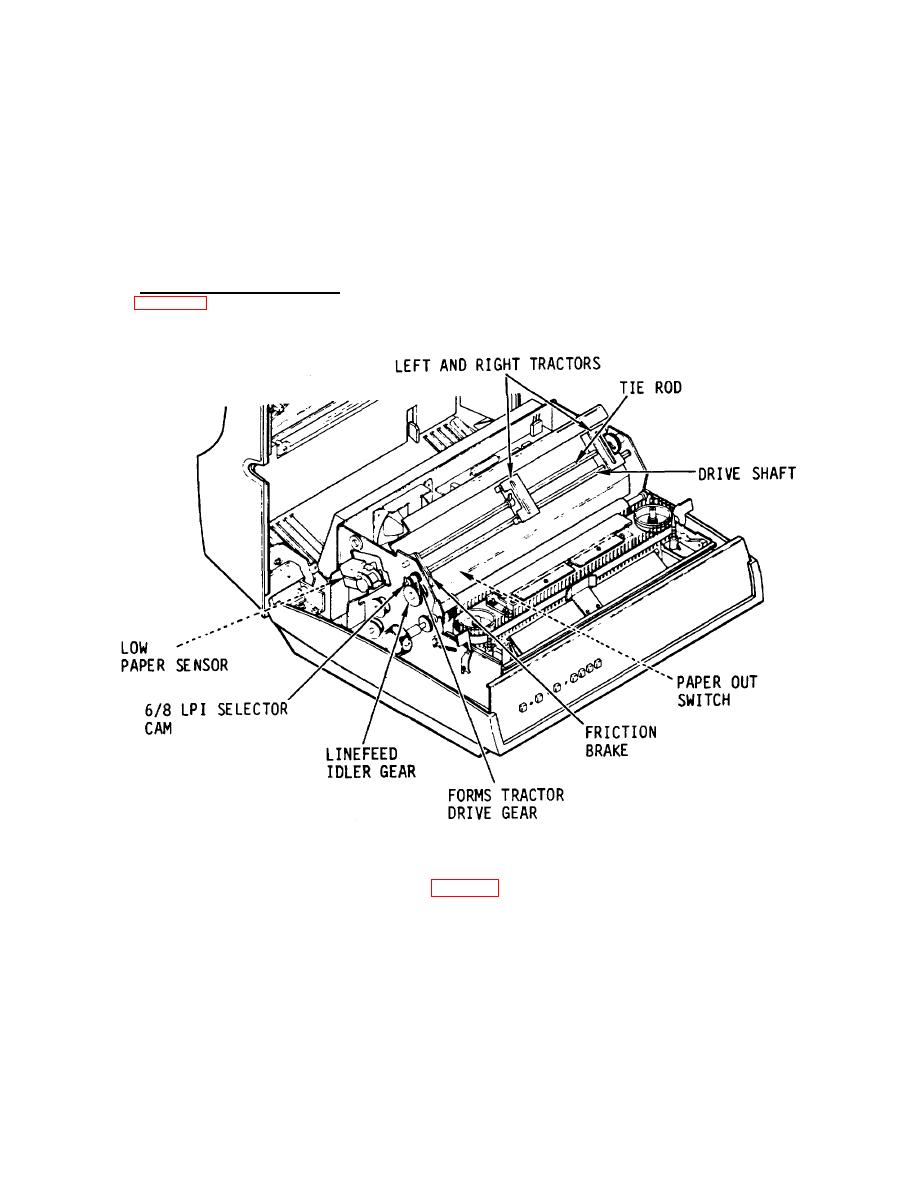

d. Paper Handling Components. The paper is moved through the printer by the interaction of paper handling

components (fig. 2-7) which consist of the right and left tractors, tie rod, drive shaft, friction brake, 6/8 lines per inch (lpi)

selector cam, low paper sensor, paper out switch, and platen.

Figure 2-7. Paper Handling Components

(1) The paper is advanced by rotating the platen knob manually or by electrical/ mechanical feed. The

linefeed solenoid and linefeed clutch are the components (fig. 2-8) used for normal line feed.

2-6