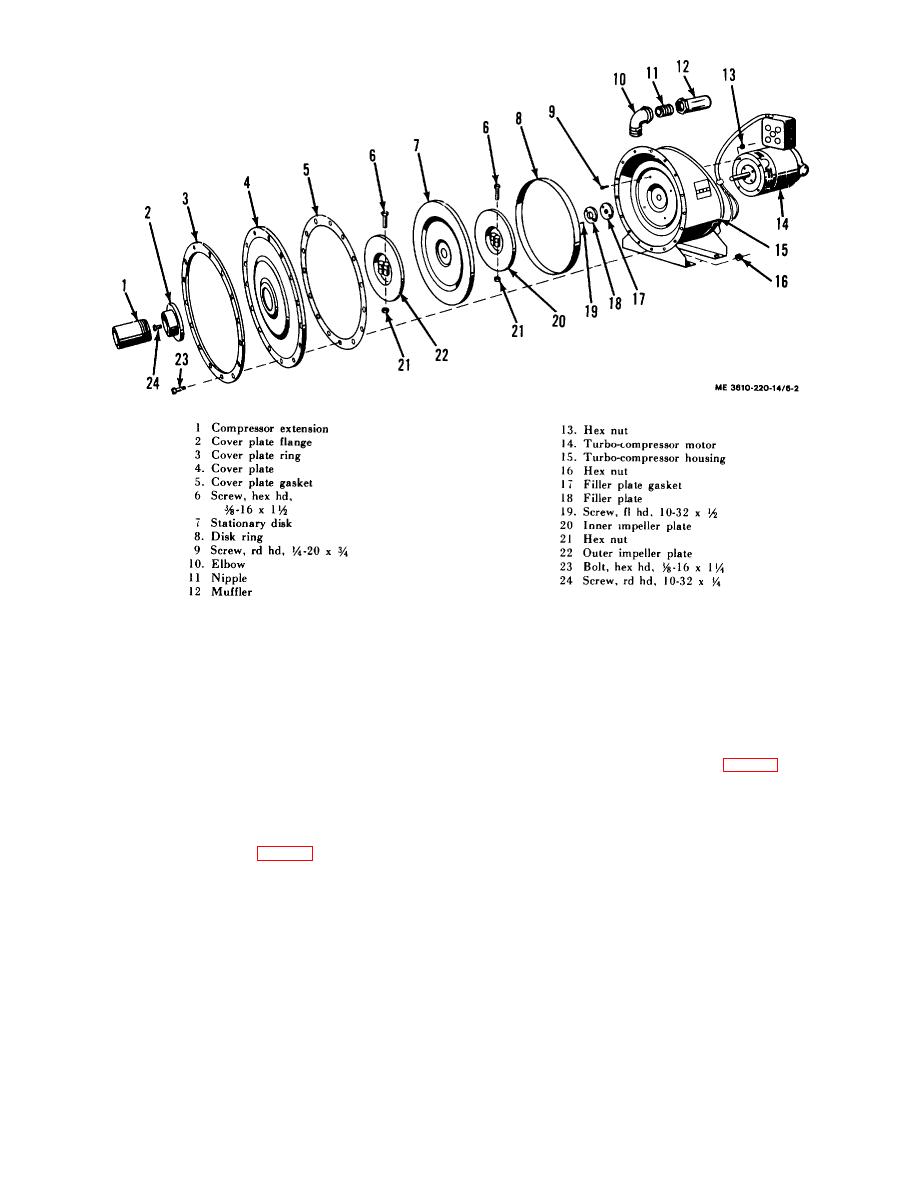

Figure 6-2. Vacuum turbo-compressor assembly, exploded view.

6-3. Vacuum Turbo-Compressor Cleaning

and Inspection

(4) Slide inner impeller plate (20) on protruding

Wash the parts of the turbo-compressor with a cleaning solvent

motor shaft and space it 0.127 plus or minus 0.002 inch from

and a clean cloth, being certain to reach threaded areas. Dry

the filler plate (18) on the turbo-compressor housing. Clamp

parts thoroughly with a clean cloth. Inspect the impeller plates,

impeller plate to shaft with two screws (6) and nuts (21).

disks, and rings for bends and distortion. Check the housing for

dents and holes. Examine the muffler for clogged filter

(5) Insert stationary disk (7, fig. 6-2) and disk ring

suppression. Replace all defective parts.

(8) into position in turbo-compressor housing (15). Slide outer

impeller plate (22) on turbo-compressor motor shaft, spacing it

6-4. Vacuum Turbo-Compressor Reassembly

0.127 plus or minus 0.002 inch from the stationary disk (7).

a. Reassembly.

Clamp impeller plate to shaft with two screws (6) and nuts (21).

(1) Screw elbow (10, fig. 6-2) and nipple (11) into

(6) Start motor with external power source and

outlet of turbo-compressor housing (15) and install muffler (12).

check impeller plate settings. Plates must rotate freely with no

binding or rubbing. Adjust impeller plate to eliminate rubbing or

(2) Position filler plate gasket (17) and secure filler

binding.

plate (18) to turbo-compressor housing (15) with two screws

(19).

(7) Position new cover plate gasket (5, fig. 62) on

turbo-compressor housing (15), and secure cover plate (4) and

(3) Position turbo-compressor motor (14) on turbo-

cover plate ring (3) to housing with 16 bolts (23) and nuts (16).

compressor housing (15) and secure with four screws (9) and

nuts (13).

(8)

Secure cover plate flange (2) to cover plate

6-2