TM 11-7025-210-10

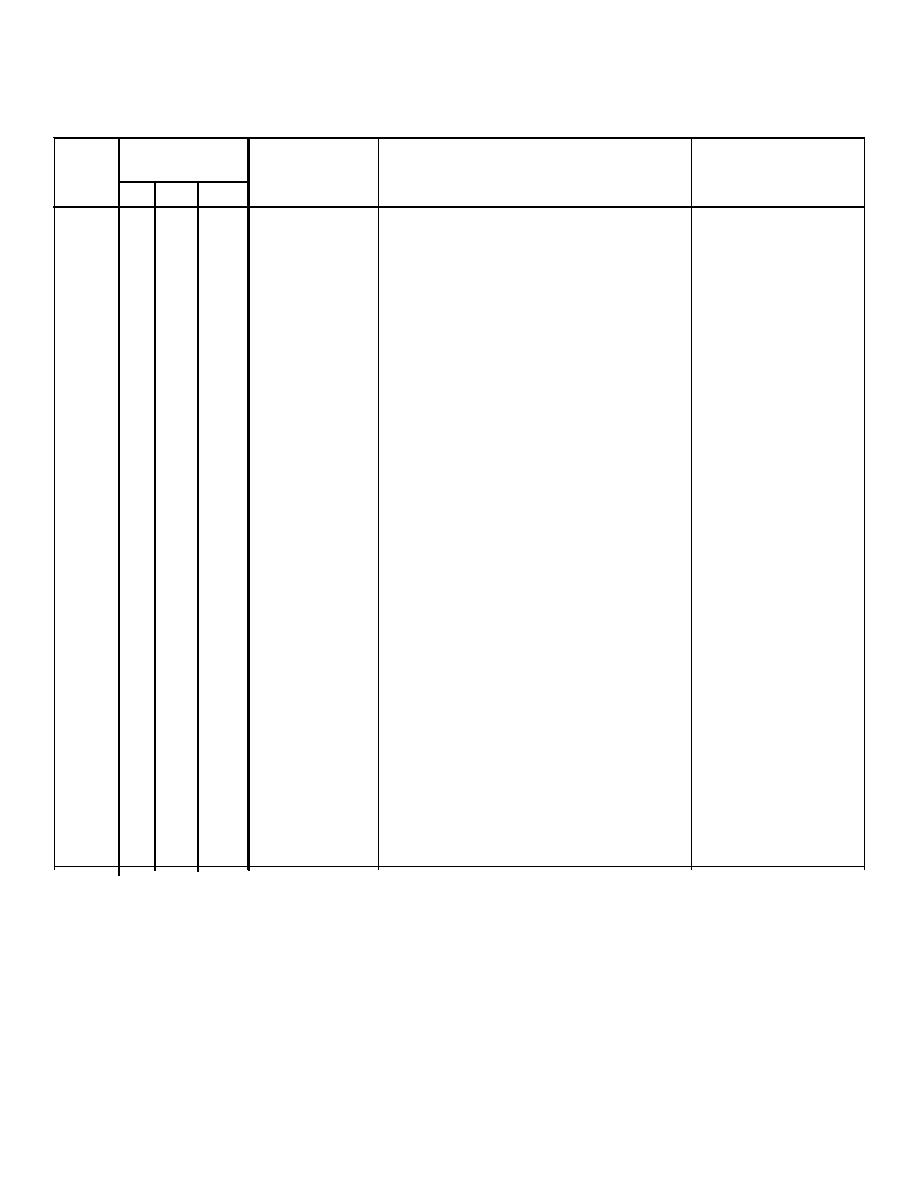

Table 2-1. Preventive Maintenance Checks and Services -- Continued

Equipment is

ITEM

INTERVAL

ITEM TO BE

NOT READY/

NO.

B

D

W

INSPECTED

PROCEDURE

AVAILABLE if:

1

Type

Check for ink buildup.

Type fingers complete-

Fingers

Clean if required.

ly smudged with ink.

2

Ribbon

Inspect ribbon condition

Ribbon torn or

Cartridge

while turning drive knob on

jammed in cartridge.

cartridge counterclockwise.

Replace if ribbon cut,

frayed, or jammed in

cartridge.

3

Ribbon

Check inking condition.

Print too light to

Run self-test. If neces-

read or self-test

sary, install re-inker.

will not run.

4

VFU Tape

Check condition. Replace

Tape torn or damaged.

if torn or damaged.

5

Platen

Check that platen is

Platen jammed.

properly seated. Push in

platen drive knob and turn.

6

Line

Clean, as follows:

Printer

Exterior/

1. Dampen soft lint-free

Paper

cloth with water. Wipe

Shield

paper shield.

2. Dampen cloth with liquid

cleanser. Wipe top and

bottom cover, pedestal, and

control panel.

3. Rinse cloth. Wipe

printer clean.

4. Using soft dry cloth,

wipe printer and paper

shield dry.

2-5