TM 11-6730-235-35

c. Procedure (Continued)

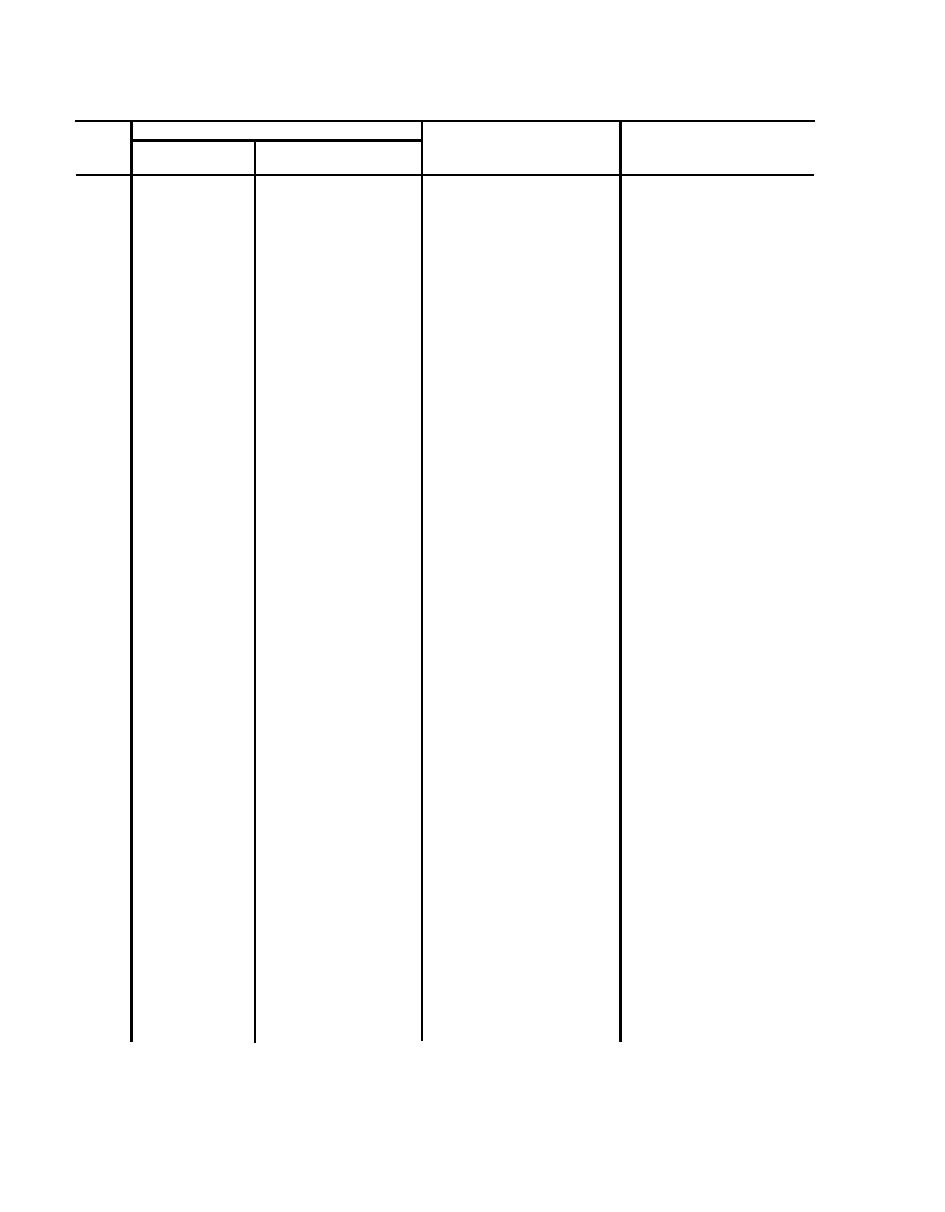

Control settings.

Step

Test

Equipment

Test procedure

Performance standard

NO.

under test

equipment

3

Controls may be in

a. Operate focus knobs to

None

a. Movement shall be smooth

move focusing arm holster

any position.

with no slipping of focus

to upper and lower ex-

knobs on their shafts and

tremes of travel.

no catching of pinion gear

on rack of arm and post

assembly; travel shall not

bring focusing arm holster

past either limit stop.

b. Move lens head assembly

b. Lens head assembly shall

about its pivot point.

pivot smoothly without

binding or stopping.

4

c. Examine lenses on lens

None

Controls may be in

a. Lenses shall not be

any position.

head assembly.

chipped, cracked, broken,

fogged, or dirty.

b. Examine mirror in lens

b. Mirror shall be clean with

head assembly by looking

no chips, cracks, breaks, or

through front lens.

unsilvered portions visible.

c. Examine stage glass and

c. Stage glass and fresnel lens

fresnel lens of top plate

shall be clean, with no

assembly.

chips, cracks, breaks, or

fogging.

5

None

Controls may be in

a. Check spring lock button

a. Spring lock button shall

any position.

on case assembly.

secure top plate assembly

in closed position; shall

operate to release top plate

assembly.

b. Release top plate assembly

b. Top plate assembly hinge

and swing upward.

shall operate smoothly

without binding and shall

be locked in open position

by interlock arm.

c. Press bottom of interlock

c. Interlock arm shall release

arm toward front of case

top plate assembly, per-

assembly.

mitting it to close.

d. Press down on top plate

d. Spring lock button shah

assembly.

secure top plate assembly

by latching hole in top

plate assembly.

6

None

Controls may be in

a. Release top plate assembly

a. None

any position.

and swing upward.

b. Bulb shall loosen in socket

b. Operate bulb eject lever.

so that it can be lifted out

easily.

c. Bulb shall seat securely in

c. Return bulb.

its socket.

d. Release interlock arm and

d. None.

close top plate assembly.

4-2