the center arm bracket (12) and the free-end arm bracket (13).

These members are adjustable to permit extending the arc

lamps to the required working distance and angle to the

copyboard so as to uniformly illuminate the copy for exposure.

1-4. Identification

The copying camera has 23 different identification and

instruction plates (fig. 1-8). The copyboard control switch and

lensboard control switch identification plates (A), both on the

darkroom end

1-6

of the camera, identifies the

manufacturer's H. P. rating and component movement. The

copyboard drive identification plate (B) and lensboard drive

identification plate (C) identifies the control switches.

Shutter switch plates (D), one on the darkroom end and one

on the lensboard side frame, locate and identify the shutter

switches. Copyboard and lensboard drive motor identification

plates (E) riveted to the motor frame designates the

manufacturer's name and other data. The rotation plates (F)

riveted to the frame of the copyboard and lensboard drive

motors, indicate direction of motor rotation. The turbine

identification plate (G) on the darkroom end identifies the

switch for the vacuum back turbo-compressor. Two arc lamp

switches identification plates (H), one on the darkroom end of

the camera and one on the side frame of the lensboard,

identify the switches. The two arc lamp switches (J) identify

the manufacturer and type. The vacuum back instruction

plate (K) on the vacuum housing sets forth the valve openings

for specified size negatives. The operating dial plate (L) on

the back of the copyboard gives instructions as to the suction

areas for specified size copy. The caution plate (M) mounted

on the copyboard frames, specifies instructions for the

transparency light box plug.

The positive holder light

identification plate (N) on the copyboard frame identifies

the light switch of the light box assembly. Manufacturer's

identification plates (P) attached to the lensboard side frame

and to the camera skid, include the model and serial number

of the camera. The caution plate (Q), mounted on top of the

cross support channel of the rear truss support assembly,

specifies instructions for the bellows and camera bed. The

caution plate (R) mounted on the rear truss assembly

specifies instructions for raising the camera. The two limit

switch identification plates (S) on the lensboard and

copyboard specifies the manufacturer's name and type. The

limit switch identification plate (T) on the lensboard identifies

the manufacturer and type. Arc lamp nameplates (U), on the

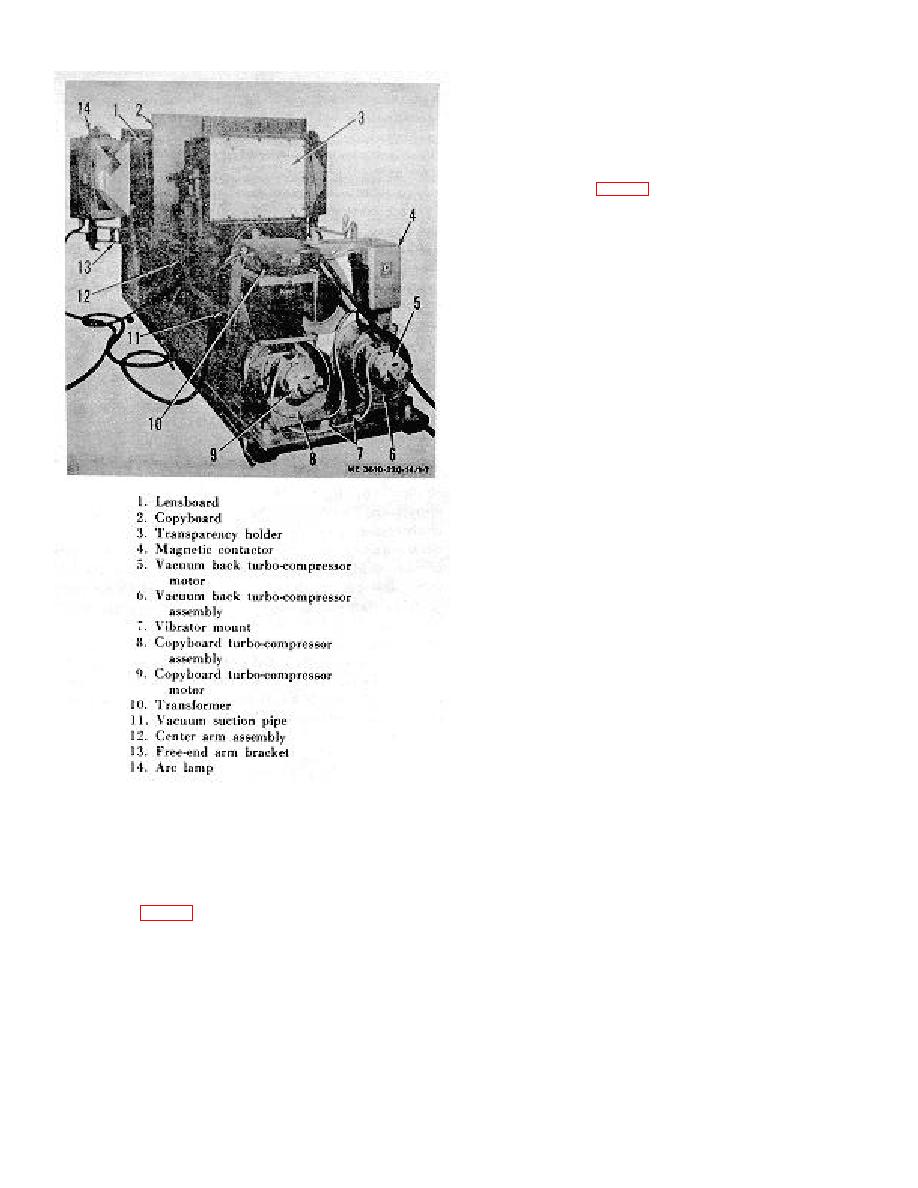

Figure 1-7. Copying camera, three-quarter view

rear panels of the arc lamps, identify the manufacturer and

type. The transformer nameplate (V), located on the

from copyboard end.

transformer side, provides the manufacturer's designation and

electrical rating. The turbo-compressor motor nameplate (W)

i. Arc Lamp Arm Assembly. There are two arc lamp

specifies the manufacturer's designation and rating. The

arm assemblies on the unit, each on opposite sides of the

turbo-compressor identification plates (X), on the compressor

camera rail and each protruding from the carriage base plate

housing, identify the manufacturer and provide electrcial and

of the copyboard. The camera arm assembly supports the

pressure data. The compressor rotation plates (Y) on the

arc lamp (14, fig. 1-7), and consists of two main structures,

compressor housing indicate rotation of motor.

1-6