TM 11-7025-210-23

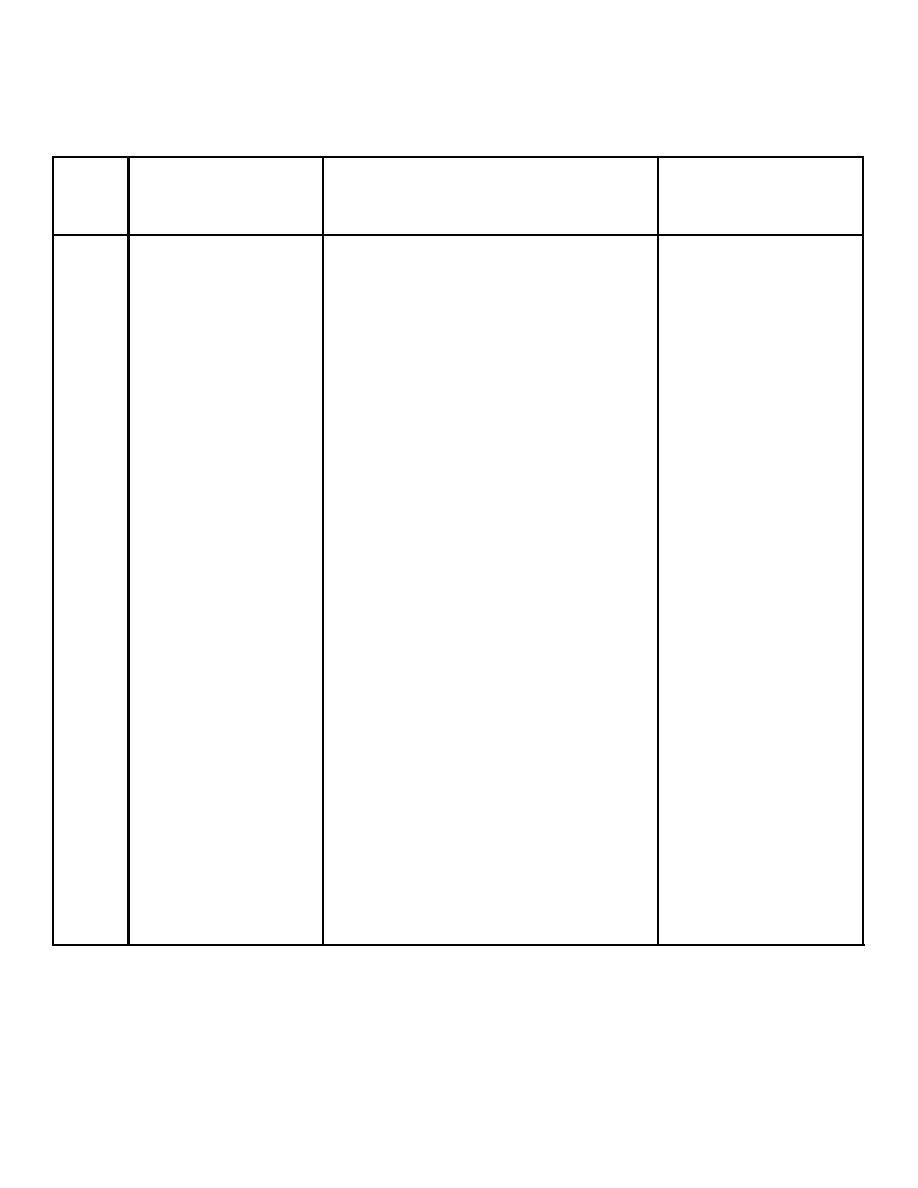

Table 3-1 . Organizational Preventive Maintenance Checks

and Services Semiannual Schedule -- Continued

Item

Item To Be

Equipment Will Be

No.

Inspected

Procedures

Reported Not Ready/

Available if

2

Print Mechanism

Lubricate left jackshaft bear-

Bearing binds.

ing by applying two drops of

oil to bearing between jack-

shaft pulley and side frame.

Lubricate right jackshaft

Bearing binds.

bearing by applying two drops

of oil on jackshaft next to

end of bearing on outside of

side frame.

3

Print Mechanism

Check adjustment of jackshaft

Jackshaft is not

Jackshaft

as follows:

properly adjusted.

1. Using feeler gauge, check

left jackshaft end play.

It should be 0.003-0.008

in. (0.08-0.20 mm) between

outside edge of left jack-

shaft bearing and left

pulley assembly.

2. Using feeler gauge, check

right jackshaft end posi-

tion. It should be flush

to 0.06 in. (1.5 mm)

beyond outside edge of

pulley.

4

Print Mechanism

Check tension of left and

Drive Belts

right drive belts.

1. Using belt tension gauge,

apply a force of 4 oz. to

center of belt span.

2. Using a machinist's rule,

measure deflection caused

by force. It should

measure between 0.05 and

0.23 inches.

3-4