TM 11-6780-225-12

(d) At least once each week if the

(b) When the equipment is reinstalled

after removal for any reason, and

equipment is not used daily, but is maintained in

standby condition (i.e., ready for immediate use) .

(c) At least once a week if the

equipment is not used daily, but is maintained in

(2) In

fixed,

transportable,

and

mobile

standby condition (i.e., ready for immediate use).

installations.

(a) When the equipment is initially

services that must be performed once each week.

installed,

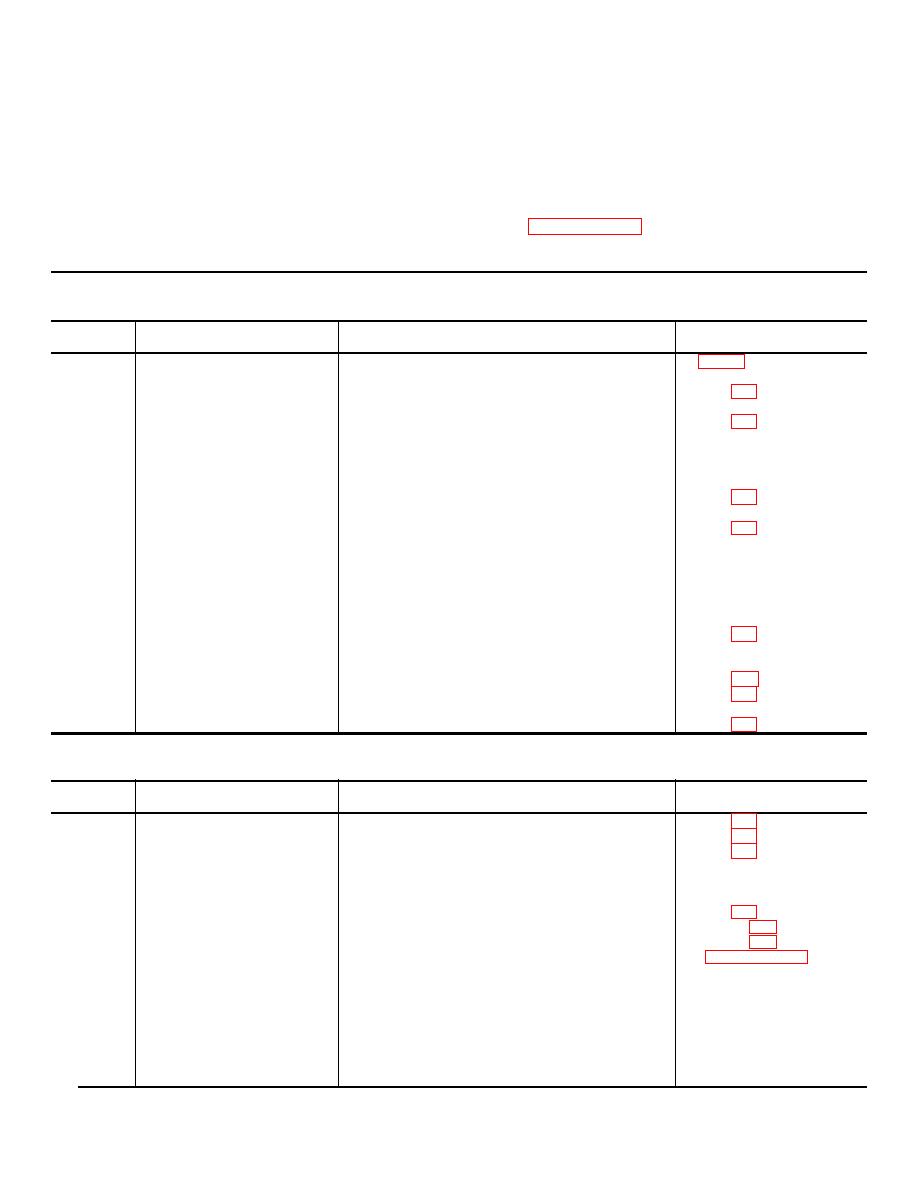

3-5. Operator's Daily Preventive Maintenance Checks and Services

Sequence

Item to be

No.

Inspected

Procedure

Reference

1

Check to see that the equipment is com-

plete.

2

Exterior surfaces

Visually inspect for signs of deteriora-

Para 3-7

tion (dirt, corrosion, fungus, etc.)

3

Electrical cables

Check all electrical cables and their as-

Para 3-9

sociated connectors for worn, cracked,

broken, and frayed areas. Replace

electrical cables that have damaged

wiring or broken connectors.

4

Connectors

Check the tightness of all connectors and

Para 3-9

check for leaks.

5

Controls and indicators

Observe that the mechanical action of

Para 3-9

each control is smooth and free of ex-

ternal or internal binding, and that

there is no excessive looseness. Also,

make sure glass on indicators is secure,

and that indicator pointers register

zero with no input.

6

Water pump

Check that water pump is operable,

Para 3-9

maintains required pressure, and does

not run constantly.

7

Filter

Check differential pressure at filter.

Para 2-8e

8

Water heater

Check that water temperature remains

Para 3-9

approximately constant.

9

Circuit breakers

Check for constant tripping

Para 3-9

3-6. Operator's Weekly Preventive Maintenance Checks and Services

Sequence

Item to be

No.

Inspected

Procedure

Reference

1

Daily preventive maintenance. Perform the daily preventive maintenance.

Para 3-5

2

Tubes and hoses

Check for evidence of physical damage

Para 3-9

3

Valves

Check without flow or pressure to as-

Para 3-9

certain proper mechanical function,

and with flow to check for no leakage

due to worn valves.

4

Air conditioner ducts

Inspect for leaks

Para 3-9

5

Exhaust fans

a. Inspect and clean, as required

b. Check that air is being exhausted

6

Water supply system strainer Check for dirt

and filter.

7

Publications

Check that all publications are complete,

DA Pam 310-series

serviceable, and current.

8

Modifications

Check DA Pam 310-7 to determine if

DA Pam 310-7

new applicable MWO's have been

published. ALL, URGENT MWO's

must be applied immediately. ALL.

NORMAL MWO's must be scheduled.

3-2