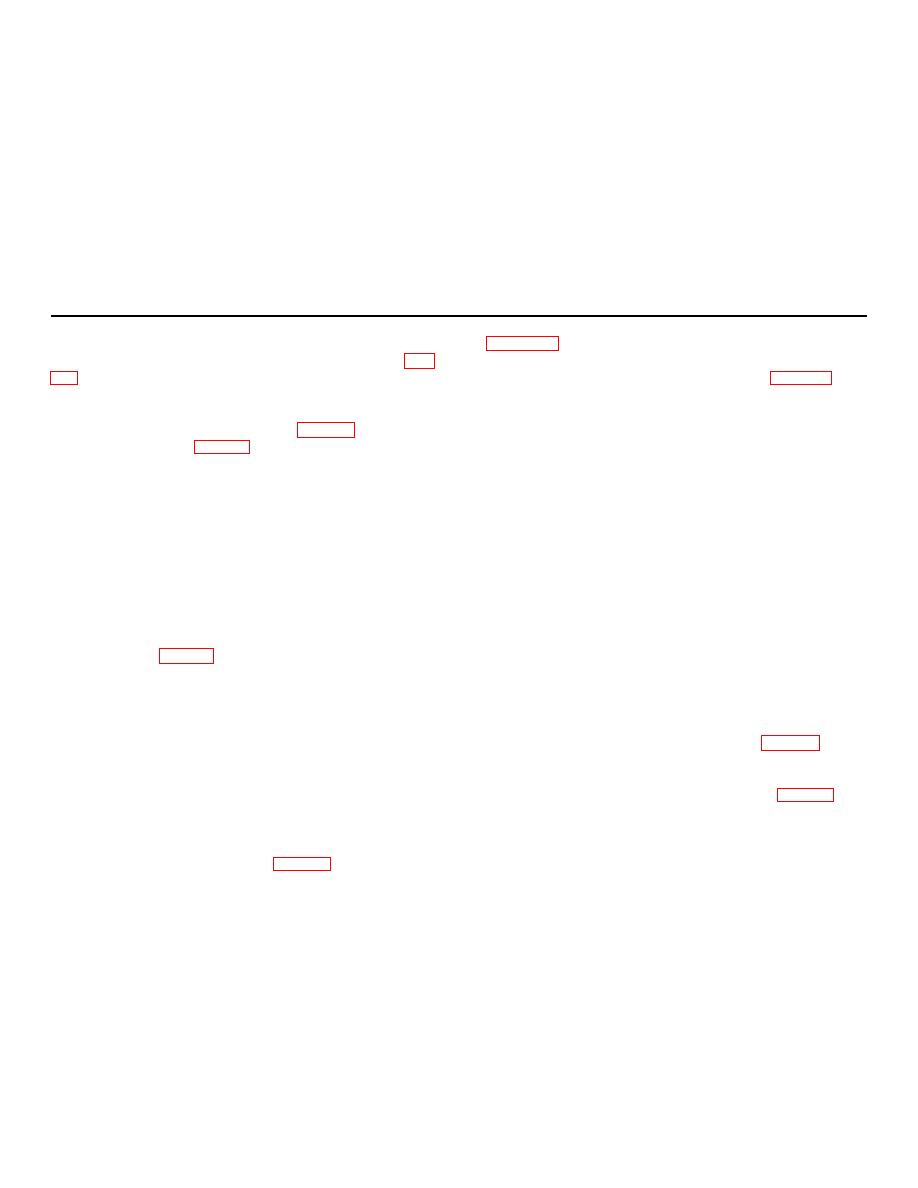

TM 11-6720-242-35

24

Lower diaphragm blade

14

Shim (MP105)

1

Focal plate (MP66)

(MP8)

15

Cam follower arm (MP5)

2

Screw (H44-47)

25

Pivot plate (MP64)

16

Screw (shoulder) (H8)

3

Pin (MP59-60)

26

Spring (MP117)

17

Cam follower (MP26-27)

4

Carriage assy (MP41)

27

Ball bearing (MP20)

18

Bearing (MP12-15)

5

Shaft and bushing (MP88)

28

Retainer ring (MP70)

19

Spring (MP112)

6

Set screw (MP82)

29

Spacer (MP377)

20

Retaining ring (MP68-69)

7

Shaft (MP89)

30

Spacer (MP378)

21

Diaphragm guide blade

8

Set screw (MP80-81)

31

Retainer ring (MP71)

(MP52)

9

Lens assy (MP57)

32

Spacer (MP377)

22

Screw (H34-38)

10

Screw (H40-43)

33

Spacer (MP378)

23

Upper diaphragm blade

11

Shim (MP102)

34

Spacer (MP379)

(MP9)

12

Shim (MP103)

129

Housing (MP55)

13

Shim (MP104)

Figure 3-3(1)-Continued.

(1) Remove aec assembly from camera body

and conformity to the following special instructions.

(2) Rotate the imc shaft assembly (144, fig.

(2) Remove three screws (43, fig. 3-3 (2))

securing servo motor (44).

shaft pin in the slot is pointed upward. Cam(160)on the

opposite end of shaft(169)will then be positioned for

(3) Release motor support (55) by loosening

insertion into the cam follower (17, fig. 3-3 (1)) on the

screw (46) and nut (45).

carriage assembly (4, fig. 3-3 (1)).

(4) Withdraw motor.

(3) Hold the aec assembly as shown in figure

3-5 and lower it into the body drive housing. The two

(5) Remove friction clutch (47) from the

pins extending downward from the carriage must be

motor shaft by removing two screws. Do not remove

inserted in the respective counterweight arms and the

retaining ring (48).

imc cam will then be inserted into the cam follower on

b. Replacement.

the carriage assembly without force.

3-11. Removal and Replacement of Sensitive Switch

(1) Install a new friction clutch on the shaft of

(Puck Switch)

servo motor (44). Apply glyptal 752F (GE) to the threads

a. Removal.

of attaching screws.

(1) Tag and disconnect the wire leads from

(2) Mount servo motor (44) in the reverse

puck switch (43, fig. 3-4 (2)).

sequence of the removal procedures.

3-13. Removal and Replacement of Photocell

(2) Loosen the adjusting screw and remove

Window

screw (44) from the bracket. Remove the puck switch.

a. Removal.

b. Replacement.

(1) Remove cover assembly (7, fig. 3-4 (1)).

(1) Install a new puck switch on switch

(2) Dissolve

adhesive

with

methyl-

bracket (39) in the reverse of the removal procedures.

ethylketone (MEK) to remove the glass (38, fig. 3-4 (2)),

Adhere to the following alinement instructions:

scrape recess clean with sharp blade.

(2) See that the switch bracket (39) is

b. Replacement.

mounted so that the switch actuator and the white line

on the cam form a straight line (fig. 3-6). Ap3ly glyptal

(1) Apply a coating of adhesive M6123 (U.S.

(adhesive) to edge of the two switch -racket screws,

overlapping slightly onto bracket surface.

Royal No. 89616)

sparingly to the three edges of

window glass (38).

(3) Adjust the switch position with the

adjusting screw so that the switch is actuated when the

(2) Insert the glass into the recess and press

switch actuator and the red line on the cam forms a

the cement into contact with the metal. Be certain no

straight line. After adjustment, apply glyptal to both puck

excess of cement is forced into the inside area and that

switch adjusting screws.

the adjacent gear has ample rotational freedom.

3-12. Removal and Replacement of Servo Motor

Friction Clutch

(3) Clean both glass surfaces to permit a full

a. Removal.

penetration of light.

Change 3

3-9