TM 11-6720-242-35

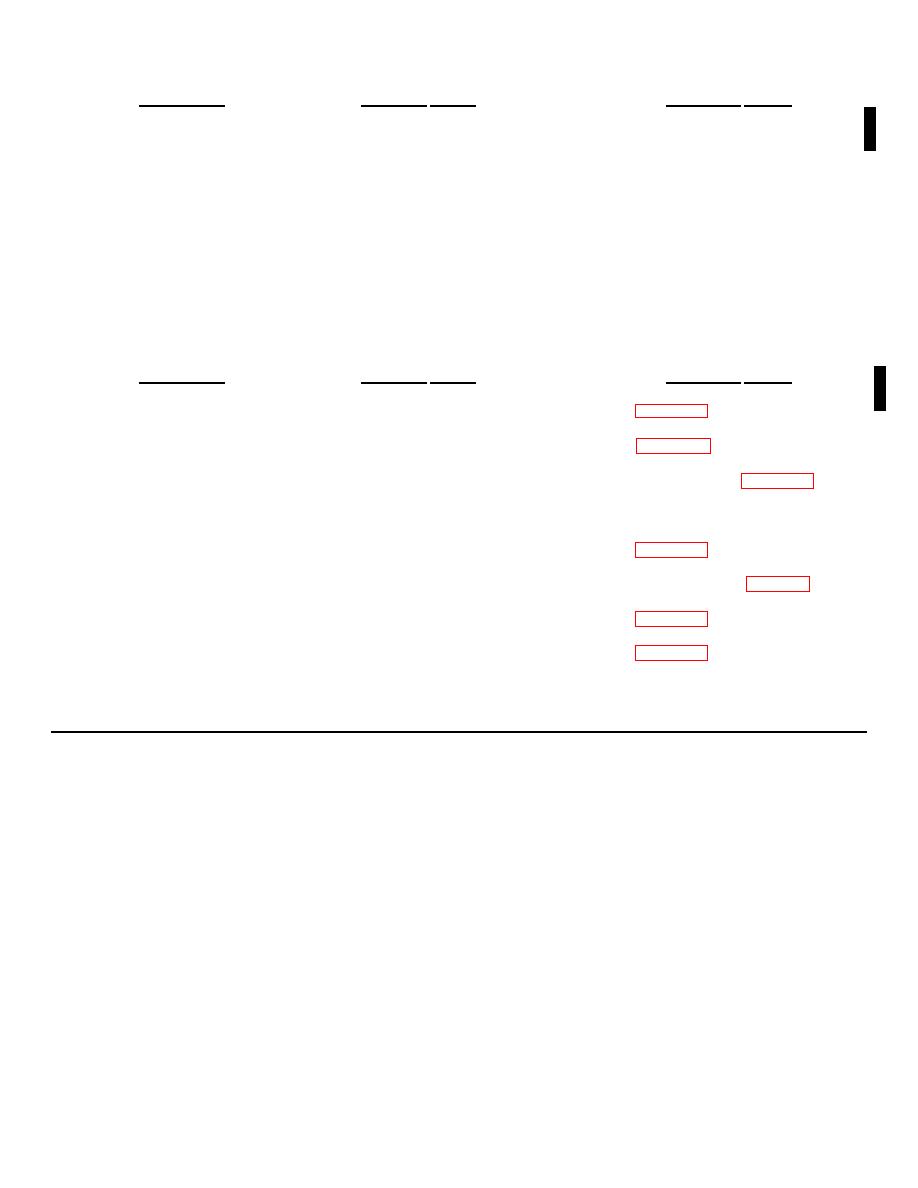

(3) Troubleshooting control panel.

Malfunction

Probable Cause

Corrective Action

Item

1

Extra picture circuit does not

EXTRA PICTURE switch S5 .................. Check switch operation and replace

function

if found faulty (fig. 6 11).

2

No V/H input to scaling

CAMERA SEL switch S4 ....................... Check switch operation and replace if

network on control board

necessary.

assembly.

3

No +28 vdc or 115 vac power POWER switch S1................................. Check switch operation and replace

input to interface board

if necessary.

assembly.

4

Camera does not operate in

OPERATE switch S2 ............................. Check switch operation and replace

autocycle mode

if necessary.

5

No V/H voltage ......................... V/H SEL switch S3................................. Check switch operation and replace

if necessary.

(4) Troubleshooting magazine.

Malfunction

Probable Cause

Corrective Action

Item

1

Scratches on film ...................... a.

Burs on pressure plate.................. a. Replace pressure plate assembly

b.

Burs on film guides....................... b. Replace pressure roller assembly

2

Film disengages from

a.

Spring in keeper block exhausted, a. Install new spring in keeper

sprockets

damaged or left out

block assembly (para 3-41).

b.

Keeper rollers damaged ............... b. Replace keeper block assembly

(para 341).

3

Adas image out of focus

a.

Roller follower damaged............... a. Replace pressure roller assembly

on film

b.

Adas pressure plate twisted out b. Turn adas pressure plate until

of position

it seats properly (fig. 3-17).

4

Film does not advance

a.

Roller damaged or does not rotatea. Replace pressure roller assembly

smoothly

smoothly

b.

Film guides bent or

b. Replace pressure roller assembly

damaged

5

Film spool cannot be properly a. Damaged pivot on spindle

a. Replace affected spindle assembly

attached to spindle

assembly

(para3-43).

b.

Damaged slot on film spool .......... b. Replace film spool (par 844).

6

Film does not take up

Bent or damaged film spool ................... Replace film spool (para 344).

3-5. Signal Substitution Tests

(2) Set the test set. switch to position 1 an(

a. General. The special test fixtures described in

check for a meter reading of +15 +1 vdc between pins

2M and 1C.

paragraph 33 provide necessary signal substitutions for

(3) With the test set switch set to position 1

testing a power supply board assembly and a scan heat

check for a meter reading of -165+1 vdc between pins

sink assembly.

b. Testing Power Supply Assembly. Insert the

2Z and 1C.

(4) Reset test set switch to position 2 and

power supply board assembly in the special test fixture

check for a meter reading of + 15 + 1 vdc between pins

shown in figure 3-1. A vacuum tube voltmeter will be

2M and 1C.

needed.

(5) With the test switch set to position 2,

NOTES

check for a meter reading of -15 +1 vdc between pins Z

1. When the designated value or condition of

and 1Z.

(6) Check for a meter reading of 6+0.6 vac

a test is not obtained, trace the

between pine 2D and 1C.

malfunctioning circuit in figure 6-17 to

(7) Check for a meter reading of 29 + 8 vac

isolate the faulty part or assembly for

between pins 2J and 1C.

replacement.

(8) Check for a meter reading of +21 8S vdc

2. The pins designated in the following

between pins 1Y and 1C. Then check for a maximum

procedure refer to the test fixture.

meter reading of 4 vac, rms, between the same pins.

(1) Set the power on.

Change 1 3-5