TM 11-6720-242-35

3-4. Localizing Troubles

bly to be plugged into a connector that is wired to the

a. General. If,. trouble was not localized at the

circuits shown.

organizational level by checks performed with Test Set,

f. Fabricating Scan Heat Sink Assembly Test

Camera LS-86A or by other means, refer to the

Fixture.

troubleshooting charts.

b. Troubleshooting Charts. The troubleshooting

(1) The heat sink assembly test fixture is not

supplied as a camera component. It must be made.

charts below provide continuity of analysis from

symptom, to probable trouble, to correction. The charts

(2) See figure 3-2 and construct a test fixture

will aid in tracing a malfunction. The detailed test

that permits connecting the heat sink to a connector that

procedures of paragraph 3-5 should then isolate the

is

wired

to

the

circuits

shown.

trouble to an assembly or part.

(1) Troubleshooting camera body.

Probable Cause

Corrective Action

Malfunction

Item

1

AEC malfunctioning .................. a.

Photocell assembly ............................ a.

Replace photocell assembly

b.

Defective servo motor, feedback

b.

Send AEC assembly to higher

resistor, or mechanism

category of maintenance.

2

Servo motor friction clutch

Worn or damaged parts ............................... Replace friction clutch (para 3-12).

defective.

3

ADAS not recording

a.

Defective RHA assembly.................... a.

Replace RHA assembly

photographically

b.

Damage to lens and mirror

b.

Send AEC assembly to higher

assembly

category of maintenance.

4

Sensitive (puck) switch

a.

Mounting alinement ............................ a.

Realign (para 3-1).

b.

Loose electrical connection ................ b.

Examine connections; secure

where necessary.

c.

Switch actuator adapter

c.

Send to higher category of

maintenance for

replacement.

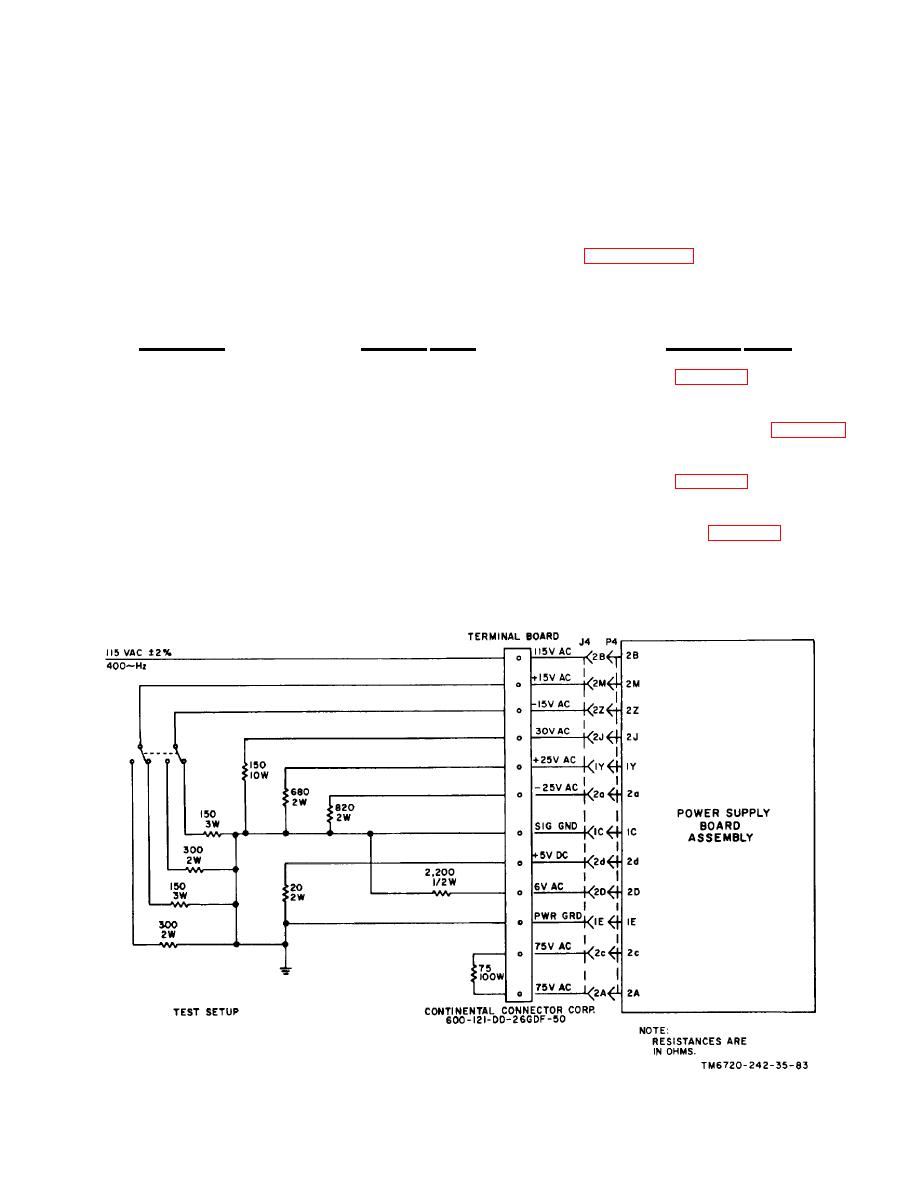

Figure 3-1. Power supply board assembly, test setup.

Change 1 3-3