TM 11-7025-232-10

a. Character Band Drive System. The character band is a continuous steel loop

w h i c h contains the raised print characters, and the necessary timing and index

marks. The character band produces print characters with a horizontal spacing of

t e n characters per inch. The character band is mounted directly under a hinged

c o v e r behind the ribbon cartridge. The character band, which is operator

r e p l a c e a b l e , is mounted over two pulleys, one of which is driven by a dc motor

w h i c h rotates the character band in a counterclockwise direction at a constant

v e l o c i t y . V e r t i c a l travel of the band is controlled by tension and edge guide

bearings located along the lower edge of the band. T h e printer processor circuit

b o a r d provides the logic control and protection of band overload conditions, and

a l s o initiates start up and shut down procedures.

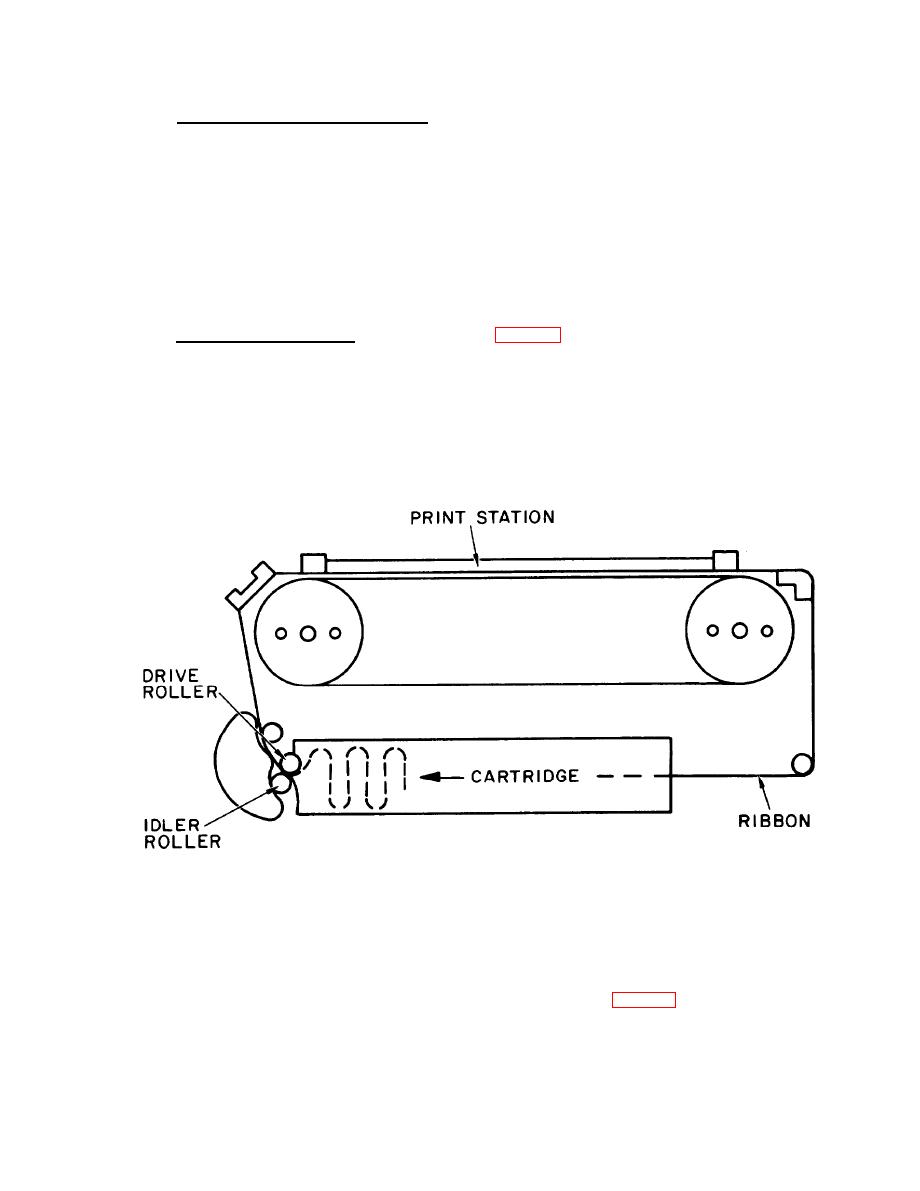

b. Ribbon Drive System. Ribbon drive (fig. 1-5)

i s controlled by a belt-driven

c a p s t a n drive roller whose motion is synchronized with character band rotation.

T h e ribbon, which consists of a continuous loop, is pulled past the print station

b y means of the belt-driven capstan drive roller in conjunction with a counter

r o t a t i n g i d l e r r o l l e r . T h e ribbon drive then refolds the ribbon in fanfold fashion

a n d restores it into position in the ribbon cartridge.

Ribbon Drive

Ribbon motion is monitored by a ribbon motion sensor (fig. 1-6) which consists of a

r o t a t i n g magnetic capstan coupled with a hall effect switching device. The ribbon

motion sensor is also coupled with a ribbon jam detector switch which will be

I f ribbon motion stops or

a c t i v a t e d if the ribbon wraps around the ribbon rollers.

a ribbon jam is detected the ribbon motion sensor line is opened to generate a

r i b b o n motion and ribbon jam fault indication.

1-13