TM 10-3610-203-14

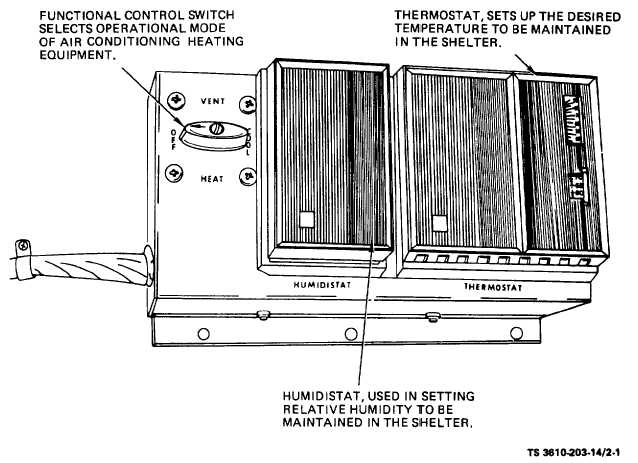

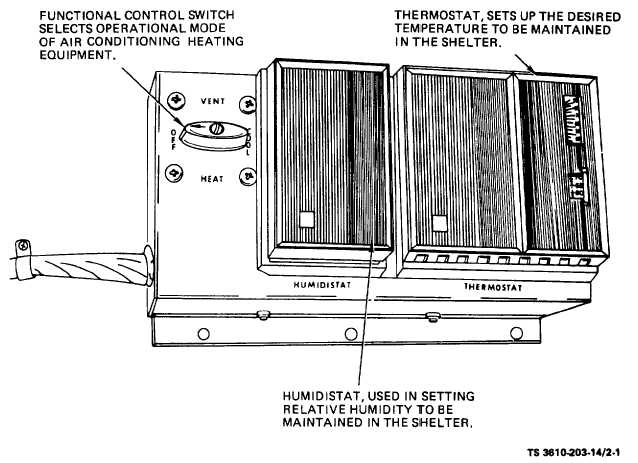

Figure 2-1. Air Conditioner Controls.

2-3. Operation

This paragraph provides generalized operating procedures for the information and guidance of the personnel

responsible for the operation of the printing plant and the installed equipment. More detailed information pertaining to

equipment operation is contained in the various commercial manuals supplied with the equipment.

a.

Duplicating Machine and Stacker. The Addressograph Multigraph Model 1250 Multilith Offset duplicator is

electrically operated and is ready for operation when the unit power cord is inserted into the adjacent polarized wall

receptacle. The duplicating machine is of the offset process type, whereby the latent image on the master receives

moisture from the dampener mechanism and ink from the inker mechanism for every revolution of the master cylinder.

A rubber covered blanket cylinder rotates in contact with the inked image on the master cylinder, transferring the image

to the blanket cylinder. An impression cylinder rotates against the blanket cylinder while paper is fed between the

impression and blanket cylinders. In this manner, the image on the blanket cylinder is transferred to the paper. The

receding stacker which forms a part of the duplicating machine provides mechanical jogging of the duplicated material on

a rubber tired paper truck, the downward speed of which is adjusted to correspond with the upward speed of the

duplicating machine paper magazine. An infrared lamp mounted above the paper truck speeds the drying of the

duplicated material.

(1)

Duplicating machine controls. Duplicating machine controls are illustrated in figure 2-2. Machine speed

is variable through a range of 4,500 ipr (impressions per hour) to 9,000 ipr. A manually reset sheet counter has a

registration capability of 99,999, registering only those sheets which pass through the machine and not machine

revolutions.

2-2